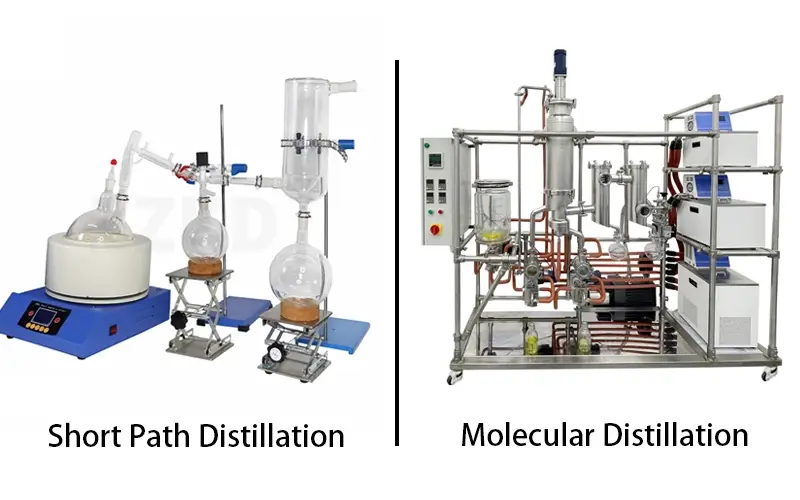

Molecular Distillation System

Molecular distillation delivers unparalleled purity and efficiency

leveraging advanced vacuum technology and precise temperature control to preserve heat-sensitive compounds and enhance product quality—elevate your process with cutting-edge separation solutions.