What Is the Working Principle of a Film Evaporator?

A Friendly Guide to Understanding and Choosing Wiped Film Evaporation Technology

Introduction: Understanding Film Evaporators

The chemical industry is filled with unit operations that sound intimidating at first. Yet, once the jargon melts away, most of them follow surprisingly simple physics. Film evaporators—especially the wiped film evaporator (WFE)—belong to this category. They quietly separate heat-sensitive or viscous products in laboratories, pilot facilities, and full-scale plants around the world.

This article walks through the working principle of a film evaporator in plain English, explains where the wiped film design shines, and answers the questions that typically come up when engineers or entrepreneurs look for the right evaporation technology.

1. The Core Working Principle

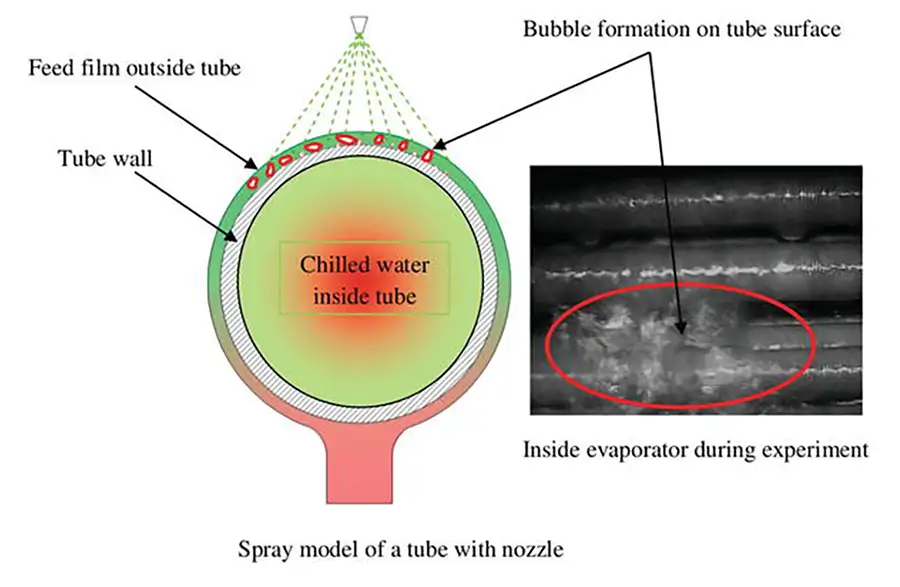

A film evaporator creates a thin liquid film on a heated surface. Because the film is only fractions of a millimeter thick, the internal resistance to heat transfer drops dramatically, allowing volatile components to vaporize quickly at temperatures that would otherwise degrade the product.

Picture pouring syrup onto a hot plate versus spreading it into a paper-thin layer: the second scenario removes the sticky fluid barrier that keeps heat from entering the liquid. The same logic applies in a cylindrical film evaporator— only the fluid coats the inner wall of a vertical tube, while mechanical wipers constantly renew the film.

Fun fact: According to data published by Bühler Technologies, a wiped film evaporator can reduce residence time to less than one second, whereas a conventional falling film unit may require 20–60 seconds for the same duty.

2. Breaking Down the Components

Each component in a wiped film evaporator has a specific function that contributes to its efficiency:

| Component | Main Function |

|---|---|

| Heat Jacket | Supplies precise temperature to the evaporating surface through thermal transfer fluid |

| Rotor/Wiper System | Spreads feed into a uniform film, prevents fouling, and constantly renews the film surface |

| Vapor Outlet | Guides volatile molecules toward the condenser with minimal pressure drop and turbulence |

| Condenser | Liquefies vapor almost immediately, lowering product temperatures and preventing degradation |

| Cold Trap | Catches stray vapors to optimize vacuum efficiency and protect vacuum pumps |

Each part is engineered to minimize the distance molecules travel from liquid to vapor to condensate. The net effect is a highly gentle separation even for high-boiling or thermal-labile compounds.

3. Frequently Asked Questions

The film thickness typically ranges from 100 µm to 300 µm. The precise thickness is maintained by the wiper system and varies with fluid viscosity and rotor speed. Anything thicker would slow heat transfer; anything thinner risks dry spots and hotspots that degrade the product.

Compared with alternative systems, the wiped film evaporator maintains this thickness automatically, because its spring-loaded PTFE or stainless wipers adapt to viscosity and flow rate in real time.

4. Why Wiped Film Evaporation Excels

The wiped film design solves three bottlenecks that often plague falling film or flash evaporators:

Pressure management: Minimal pressure drop despite viscous materials

Thermal protection: Residence time reduced to seconds instead of minutes

Material handling: Uniform film formation even with difficult or fouling feeds

By contrast, a WFE runs at deep vacuum (1 Pa or below), slashes residence time to a heartbeat, and lets mechanical wipers bulldoze fouling layers before they stick. That is why WFEs dominate the purification of cannabinoids, vitamins, specialty polymers, and heat-sensitive oils.

Market growth: According to a 2023 market survey by Grand View Research, global demand for wiped film and short path molecular distillation equipment is projected to grow at 7.4% CAGR through 2030. This underlines the technology's expanding footprint beyond niche pharma applications.

For a side-by-side specification sheet—including throughput, surface area, and molecular distillation price—feel free to visit our equipment overview page.

Vacuum level wins. Lower absolute pressure lets you drop boiling points by 80–120 °C, dwarfing the gain you'd get from tinkering with jacket temperature alone. Once vacuum is optimized, you can fine-tune surface temperature for flowability and vaporization efficiency.

5. Real-World Applications & Solutions

Wiped film evaporators solve specific challenges across multiple industries:

| Feed Material | Challenge | WFE Solution |

|---|---|---|

| Cannabinoid crude oil | Highly viscous, degrades above 180°C, prone to clogging | Deep vacuum & constant wiping keep temperature ≤140°C and prevent residue buildup |

| Omega-3 fish oil | Delicate compounds, off-odors at high temperatures | Short residence time (1-30 sec) preserves nutritional integrity and flavors |

| Silicone polymer | Extremely high viscosity, heat sensitivity | Robust rotor powers through thick feeds without thermal degradation |

| Essential oils | Complex mixtures, terpenes sensitive to heat | Fractionation capabilities separate compounds at low temperatures |

| Resins & waxes | High melting points, viscous behavior | Wiper system maintains fluidity at controlled temperatures |

Curious about how a molecular distillation system integrates downstream of a WFE? Check out our schematic at molecular-distiller.com.

6. Automation and the Future of Evaporation

Automation increasingly pairs with thin film technology. Human operators once manually adjusted vacuum valves and wiper speeds; today PLCs and AI-driven controllers do the job. Based on a Massachusetts Institute of Technology study, AI is projected to replace 30% of jobs by 2030. That same algorithmic muscle can optimize feed flow and detect fouling in real time, letting technicians focus on quality assurance rather than knob-turning.

Our latest blog article on wiped film distillation equipmentdives deeper into predictive maintenance, if that sparks your curiosity.

Not necessarily. Modern systems allow recipe-based automation with manual override. You still steer the process; the controller keeps it on the rails through PID algorithms and predictive analytics. This hybrid approach delivers both precision and flexibility.

7. Key Takeaways

Understanding film evaporator technology leads to smarter equipment choices:

A film evaporator works by forming a thin liquid layer that boosts heat transfer efficiency

Wiped film evaporators add mechanical agitation to maintain film thickness and prevent fouling

Deep vacuum and ultra-short residence time make WFEs ideal for heat-sensitive, viscous, and high-value feeds

Modern automation improves both product quality and process economics simultaneously

Selecting the right evaporator involves balancing chemistry, economics, and scale. Our process engineers are ready to help you make the optimal choice.

Get in touch via the contact formfor pilot testing or a quotation tailored to your production goals. Solutions for lab, pilot and industrial scales available.