Trying to figure out lab distillation equipment prices? It can seem complex with so many options available today.

The cost of lab scale distillation equipment is shaped by its type, size, materials, brand, and any extra features. Generally, prices can go from a few thousand to many tens of thousands of dollars.

When I first started helping clients choose equipment, the range of prices was quite wide. But it became clear that understanding a few key things makes the decision process much smoother. As a manufacturer with over 16 years of experience, we at ZZKD want to share what we've learned. This way, you can pick the right distillation setup for your lab's needs and budget. Let's look into the details together.

What Different Lab Scale Distillation Setups Exist and How Do Their Prices Compare?

Are you puzzled by terms like rotary evaporators or molecular distillation? Unsure which one suits your work and budget?

Basic setups like simple stills or small rotary evaporators are more affordable. Advanced systems, such as short path molecular distillation or wiped film units, cost more due to their complex designs and abilities.

Understanding the different types of molecular distillation equipment is the first step. The technology used directly impacts the price. Here's a closer look:

Simple Distillation Units

These are the most basic and often the cheapest. They are good for separating liquids with very different boiling points or for simple solvent removal. Think of a classic chemistry lab setup. Their simplicity means fewer parts and lower manufacturing costs.

Rotary Evaporators

Rotary evaporators are very common in labs for gentle solvent removal. They work by increasing the surface area of the liquid and reducing pressure. Prices vary with size (e.g., 1L, 5L, 10L, up to 50L or 100L for larger scale) and features like motorized lifts or digital controls. These are a step up in cost from simple stills but offer much better efficiency for many tasks.

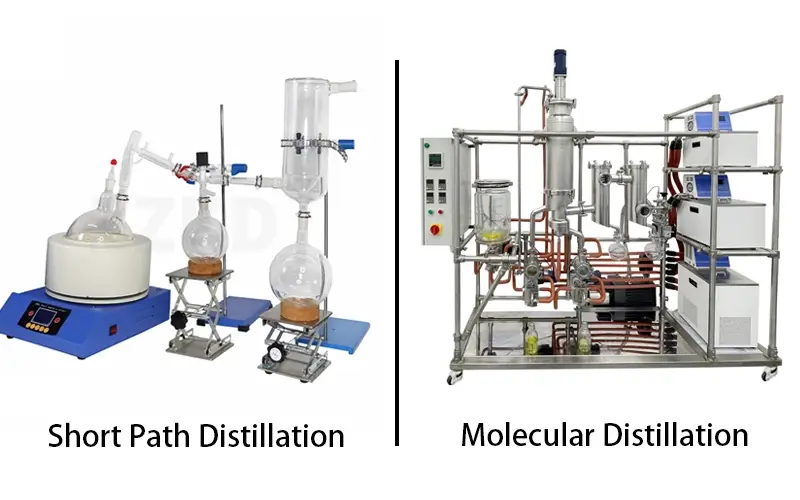

Short Path Distillation

This type is designed for separating compounds at lower temperatures under high vacuum. The short distance between the evaporator and condenser is key, minimizing sample loss and allowing for distillation of heat-sensitive materials. This specialized design makes them more expensive than rotary evaporators.

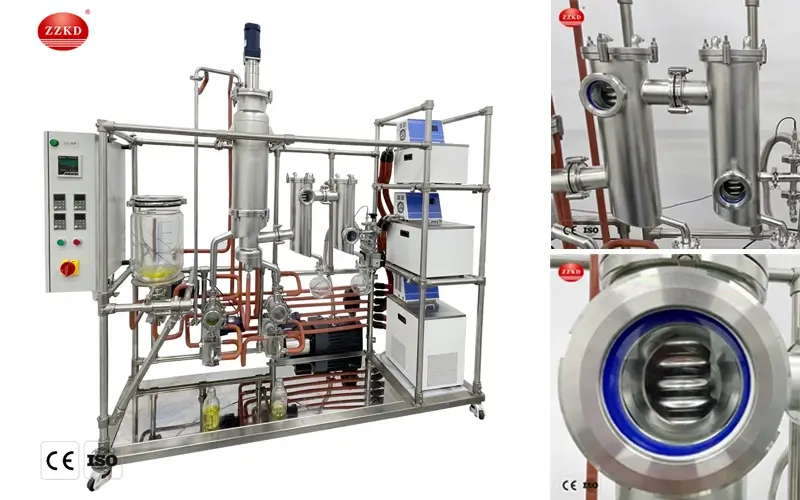

Wiped Film Molecular Distillation Evaporators

These are even more advanced. A rotating wiper system spreads a thin film of the feed material on a heated surface. This allows for very efficient evaporation and distillation of highly viscous or extremely heat-sensitive compounds. The precision engineering involved means these are usually at the higher end of the price scale. Falling film evaporators are related and also used for similar purposes, offering continuous operation benefits.

| Equipment Type | Typical Application | Relative Cost | Key Advantage |

|---|---|---|---|

| Simple Still | Basic separation, teaching | $ | Low cost, easy to use |

| Rotary Evaporator | Solvent removal, concentration | $$ - $$$ | Efficient for common solvents |

| Short Path Distillation | Heat-sensitive compounds, purification | $$$ - $$$$ | Low temperature, high vacuum |

| Wiped Film / Molecular Distillation | Viscous, highly heat-sensitive materials | $$$$ - $$$$$ | Very short contact time, high efficiency |

Choosing the right type depends entirely on what you need to do in your lab. We often talk with customers about their specific separation goals to recommend the best fit.

How Do Construction Materials and Overall Build Affect Your Equipment's Price Tag?

Do you worry about your equipment not lasting long? Is it unclear if paying more for better materials is truly a good investment?

Using top-quality materials like Borosilicate 3.3 glass and stainless steel (like 316L) adds to the cost. However, they provide great durability and resistance to chemicals, which is vital for safety and long equipment life.

The materials used to make distillation equipment are a big factor in its final price and performance. It's not just about looks; it's about safety, how long it lasts, and how well it works.

Glassware Quality

Most lab distillation units use glass. We insist on Borosilicate 3.3 glass. It's excellent for handling temperature changes and resisting chemicals. Cheaper glass might crack easily or react with your samples. The thickness of the glass and how well the joints (like ground glass joints) are made also matter. Precision joints ensure a good vacuum seal, which is critical for many distillation processes. Poor seals can lead to inefficiencies and safety issues.

Metal Components

Frames, supports, and sometimes parts that touch the product are made of metal. Stainless steel is common. We prefer using SS304 for general parts and SS316L for parts that need even better corrosion resistance, especially when working with aggressive chemicals. Better quality steel costs more but prevents rust and contamination.

Seals and Gaskets

Seals made from materials like PTFE (Teflon) or Viton are important. They need to create tight seals for vacuum and be resistant to the chemicals and temperatures used. Low-quality seals can degrade quickly, causing leaks and process failures. How these material choices affect the overall molecular distillation price can be significant, but it ensures reliability.

Overall Build and Design

A sturdy frame and stable design are also part of build quality. The equipment should be easy to assemble, operate, and maintain safely. Good design considers user ergonomics and process flow. I remember early in my career, we saw a client who opted for a cheaper distillation unit from an unknown source. During a critical experiment with rapid temperature changes, a flask cracked! It set back their research and taught everyone a valuable lesson about not skimping on material quality. Since then, I always advise looking for robust borosilicate 3.3 glassware and well-engineered supports.

Which Optional Features and Accessories Can Increase the Distillation Unit's Cost?

Feeling swamped by choices like vacuum pumps, chillers, or automation? Do you really need every available add-on for your work?

Key accessories such as vacuum pumps and temperature controllers (chillers/heaters) are often bought separately and add to the total cost. Features like automation, digital displays, and extra safety measures also increase the price but can boost efficiency and lab safety.

A basic distillation unit might be affordable, but the final cost often grows when you add necessary accessories and features. These extras can greatly improve how well the equipment works and how easy it is to use.

Vacuum System

For many types of distillation, especially short path and molecular distillation, a good vacuum is essential. This means you'll need a vacuum pump. There are different types, like diaphragm pumps (good for cleaner vacuum) or rotary vane pumps (for deeper vacuum). You might also need a vacuum controller to manage the pressure precisely, and cold traps to protect the pump. These components add to the cost but are vital for performance.

Temperature Control

Precise temperature control is also key. This involves heating mantles or oil/water baths for the evaporation flask, and chillers for the condenser. The more accurate and stable the temperature control you need, the more these units can cost. For example, a recirculating chiller that can reach very low temperatures will be more expensive than a simple tap water connection for cooling.

Automation and Digital Controls

Modern units often come with digital displays for temperature, rotation speed, and vacuum. Some offer more advanced automation, like programmable temperature ramps or automatic shutdown. While these features increase the initial investment, they can save time, improve consistency, and reduce the chance of errors in the long run.

Feeding and Collection Systems

For continuous or larger-scale operations, you might need specialized feeding pumps (like gear pumps) to introduce your material smoothly. Multiple collection flasks with switching valves can also be useful, allowing you to collect different fractions without breaking the vacuum. These add to the system's complexity and cost.

Safety Features

Features like over-temperature protection, safety shields, or sensors for vacuum leaks contribute to a safer lab environment. For work in certain environments, explosion-proof (ATEX rated) components might be necessary, and these significantly increase the price due to their specialized design and certification.

When we help customers configure a molecular distillation system, we discuss these options to balance needs with budget.

Why Does a Supplier's Reputation and Support Services Impact the Final Price You Pay?

Are you tempted by very cheap equipment you found online? Do you wonder if having good customer support really matters for this type of machinery?

Well-known suppliers, like us at ZZKD, might have higher prices. This is often because of our proven product reliability, strict quality checks (we have ISO and CE certificates), and full after-sales support, which includes available spare parts and skilled technical help.

The company you buy from plays a big role in the value you get, not just the initial price. A supplier's reputation and the support they offer are important factors that can influence cost.

Research and Development (R&D) Investment

Companies that invest in R&D to improve their products and develop new technologies often have slightly higher prices. This investment leads to more efficient, reliable, and innovative equipment. As a company with 16 years in this field, we continuously work on making our equipment better for our customers worldwide. We see ourselves as a leading molecular distiller manufacturer because of this focus.

Quality Control and Certifications

Reputable manufacturers follow strict quality control processes. Certifications like ISO 9001 (for quality management) and CE (showing conformity with European standards) give you an assurance of quality and safety. Getting and keeping these certifications adds to the cost but means the equipment meets high standards. We are proud of our ISO and CE certifications.

Warranty and After-Sales Support

What happens if something goes wrong? Good after-sales support is very important. This includes how long the warranty is, how easy it is to get spare parts, and if you can get technical help when you need it. We offer a 24/7 hotline and have English-speaking engineers ready to help. This kind of support can save you a lot of time and money if you face any issues.

Installation, Training, and Technical Expertise

Some suppliers offer help with installing the equipment and training your staff. This can be very valuable, especially for complex systems. Having access to experienced technicians who understand the equipment and your applications can make a big difference. We welcome technical exchanges and even factory visits so you can see our operations.

Global Experience and Customer Feedback

A company with a long history of exporting to many countries, like ours (87 countries and counting!), understands diverse needs and has proven product reliability. Positive feedback from thousands of users globally also shows that the equipment works well in real-world settings. This track record often comes with a price that reflects this proven value.

Conclusion

Choosing lab distillation gear means looking at your needs, the equipment's features, and supplier support to find the best value for your work and budget.