Are your valuable compounds degrading during separation? Traditional distillation too harsh for your heat-sensitive materials? You need a gentler, more efficient method for high-purity results.

Molecular distillation is a specialized liquid-liquid separation technology. It works at very low pressures and short residence times. This makes it perfect for purifying thermally sensitive, high molecular weight, or viscous materials effectively.

As a company, Zhengzhou Keda Machinery and Instrument Equipment Co.,Ltd., with over 16 years of experience in manufacturing and exporting laboratory and industrial equipment, I've seen firsthand the challenges many face. When it comes to separating complex mixtures, especially those that cannot withstand high temperatures, molecular distillation is often the answer. This process is not just about separation; it's about preserving the integrity and quality of your end product. We've dedicated ourselves to refining this technology, ensuring our equipment, like short-path distillation units, meets rigorous international standards such as ISO9001 and CE. Our goal is to help you achieve optimal purity and yield, transforming your raw materials into high-value products. This technology truly shines when you need to isolate specific molecules with minimal thermal degradation, something I believe is crucial in today's quality-driven markets.

What Makes Molecular Distillation Different from Traditional Distillation?

Are old distillation methods causing product loss? Do high temperatures degrade your valuable compounds? There is a superior way to purify sensitive substances effectively.

Molecular distillation operates under a high vacuum, drastically lowering the boiling point. This, combined with a very short path for vapor, minimizes heat exposure and thermal degradation, unlike traditional distillation methods.

The core difference lies in how we handle heat and pressure. In traditional distillation, materials often need to be heated to their atmospheric boiling points, which can be very high. This prolonged exposure to heat can destroy or alter sensitive molecules. I remember a client working with fish oils; traditional methods were breaking down the valuable omega-3 fatty acids. Molecular distillation changed that for them.

Key Distinguishing Factors:

Operating Pressure: Traditional distillation occurs at or near atmospheric pressure. Molecular distillation, however, operates under a deep vacuum (typically 0.001 mbar or lower). This drastically reduces the temperature needed for evaporation. Think of it like water boiling at a lower temperature on a high mountain – same principle, but we create the "mountain" with vacuum.

Evaporation Temperature: Because of the high vacuum, materials can be distilled at temperatures significantly below their normal boiling points. This is vital for heat-sensitive compounds like vitamins, APIs, or natural extracts.

Vapor Path (Mean Free Path): In molecular distillation, the distance between the evaporator surface and the condenser is extremely short, often just a few centimeters. This distance is designed to be less than the "mean free path" of the vapor molecules at that vacuum level. This means evaporated molecules are very likely to reach the condenser without colliding with other gas molecules or returning to the evaporator surface, increasing efficiency. Traditional stills have much longer paths.

Residence Time: The time a substance is exposed to heat in a molecular still is very brief, often just seconds. This short contact time further minimizes thermal degradation. In our designs at ZZKD, we focus on optimizing this for maximum product protection.

Essentially, molecular distillation allows us to gently coax valuable molecules out of a mixture without damaging them. It's like carefully picking out specific fruits from a basket instead of boiling the whole basket and hoping for the best. This precision makes it invaluable for high-purity applications.

How Does a Molecular Distillation System Actually Work?

Puzzled by how this advanced tech separates complex compounds? Wondering about the internal mechanics of a molecular still? Let's explore the operational principles step-by-step.

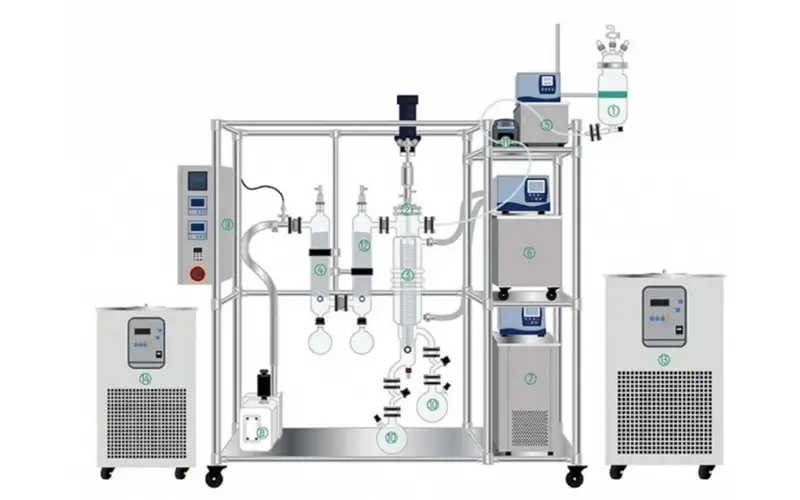

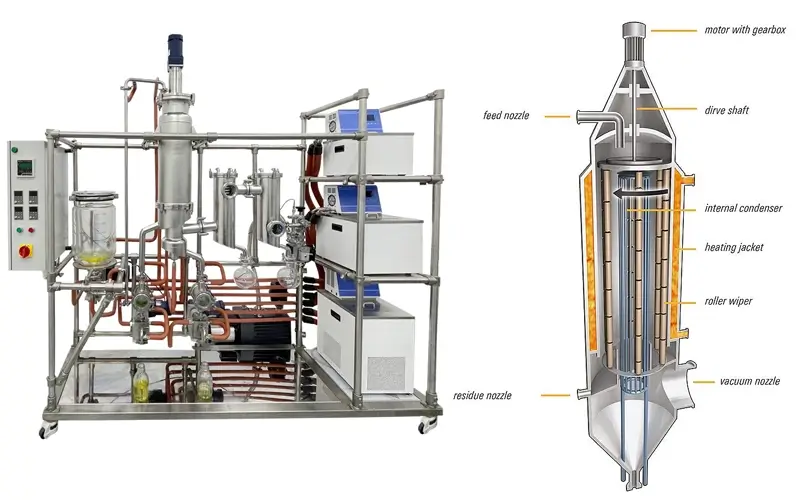

In a molecular still, degassed feed material is spread as a thin film on a heated internal surface under high vacuum. Volatile components evaporate and travel a short distance to an internal condenser, where they liquefy and are collected.

Let me walk you through the process as if you were standing next to one of our ZZKD units. Imagine your valuable material, perhaps a crude botanical extract, is ready for purification. Here's how we achieve that delicate separation:

Step-by-Step Process:

Feeding and Degassing: The raw material (feed) is first introduced into the system. Often, it undergoes a pre-heating or degassing stage to remove any dissolved gases or highly volatile solvents. This prevents issues like bumping or pressure fluctuations inside the still, ensuring smooth operation. We design our feed systems for precise control.

Thin Film Formation: The degassed feed is then carefully distributed onto a heated surface inside the main distillation body. In many systems, including our wiped-film evaporators, rotating wipers or rollers spread the material into a very thin, uniform film. This thin film is crucial because it maximizes the surface area for evaporation and ensures even heating.

Evaporation Under High Vacuum: The entire process occurs under a deep vacuum, typically generated by a robust vacuum pump system. This high vacuum lowers the boiling point of the components in your mixture. As the thin film moves across the heated surface, the more volatile components (those with lower boiling points at that pressure) evaporate.

Short Path Condensation: This is where the "short path" part is key. Positioned very close to the heated evaporating surface is an internal condenser. This condenser is kept cool. The evaporated molecules travel this short distance (often just centimeters) and, upon hitting the cool condenser surface, they lose energy and liquefy.

Separate Collection: The condensed, purified material (distillate) flows down the condenser and is collected in one receiver. The less volatile components, or residues, that did not evaporate continue down the heated surface and are collected in a separate receiver. This gives you two distinct fractions: your purified product and the remaining material.

Throughout my 16 years exporting these systems, I've emphasized to clients that the precision of temperature control, vacuum stability, and the efficiency of the wiper system are paramount for achieving high purity and yield. It's a finely tuned dance of physics and engineering. For instance, the wiper system not only creates the thin film but also agitates it, which helps to release volatile molecules more readily and prevents localized overheating.

What Key Factors Should You Consider When Choosing Molecular Distillation Equipment?

Thinking about investing in molecular distillation? Feeling unsure about which features are critical for your needs? Let's pinpoint what truly matters for optimal performance.

Key factors include the system's throughput capacity, achievable vacuum level, temperature range, material of construction, ease of operation and maintenance, and, crucially, the supplier's expertise and after-sales support.

Choosing the right molecular distillation unit is a significant decision. As a manufacturer, I always advise my clients to think beyond just the initial purchase price. The equipment needs to be a reliable workhorse for their specific application. Based on my experience helping thousands of enterprises globally, here’s what I suggest you focus on:

Critical Selection Criteria:

Processing Capacity (Throughput): Are you working on a lab scale for R&D, pilot scale for process development, or full industrial production? The size of the evaporator and the feed/discharge pump capacities will dictate the throughput (e.g., kg/hour). We offer systems from small benchtop units to large industrial setups.

Vacuum System Performance: The ultimate vacuum level the system can achieve and maintain is critical. Different materials require different vacuum levels for efficient separation. Ensure the vacuum pumps are correctly sized and of high quality. Our 24/7 after-sales support often helps troubleshoot vacuum issues, highlighting its importance.

Temperature Control Precision: The ability to accurately control the evaporator temperature and the condenser temperature is vital, especially for very heat-sensitive products. Look for systems with precise PID controllers and reliable heating/cooling circulators.

Material of Construction: The parts in contact with your product (evaporator body, condenser, wipers, seals) must be compatible with your feed material and process conditions (e.g., acidity, temperature). Common materials include borosilicate glass 3.3 for visibility and corrosion resistance, and stainless steel for larger scale or higher pressures. All our export models carry CE and ISO9001 certifications, reflecting our commitment to material quality.

Wiper System Design: For wiped-film evaporators, the wiper design (e.g., rollers, rigid blades) affects film turbulence, heat transfer, and residence time. The choice depends on the viscosity and nature of your feed.

Ease of Operation and Maintenance: How easy is the system to assemble, operate, clean, and maintain? Downtime for cleaning or repairs can be costly. We prioritize user-friendly designs and provide comprehensive manuals.

Supplier Reputation and Support: This is where our 16 years of international export experience really count. Choose a supplier with a proven track record, strong technical expertise, and reliable after-sales service. Can they provide installation support, training, spare parts, and troubleshooting? Our commitment includes a one-year free maintenance warranty and lifetime cost-price service.

I often tell potential clients to consider their future needs too. A slightly larger or more versatile system might be a better long-term investment if they anticipate scaling up or diversifying their products. It's about finding a balance between current requirements and future possibilities.

Which Industries Gain the Most from Using Molecular Distillation?

Is molecular distillation right for your industry? Could this technology unlock new levels of product purity and value for your business? Let's explore its applications.

Industries like pharmaceuticals, food and beverage, chemicals, cosmetics, and cannabis/hemp processing extensively use molecular distillation for purifying heat-sensitive, high-boiling, or viscous compounds to achieve high-value end products.

Molecular distillation is not a one-size-fits-all solution, but for certain industries, it's a game-changer. As a company that has exported to 87 countries, we've seen its transformative power across diverse sectors. Here’s where I've seen our equipment make a significant impact:

Key Industrial Applications:

Pharmaceutical Industry: This is a major area. It's used for purifying Active Pharmaceutical Ingredients (APIs), separating synthetic intermediates, concentrating vitamins (like Vitamin E), and refining fish oils for omega-3 fatty acids. The low temperature and short residence time are perfect for maintaining the potency of sensitive drugs.

Food & Beverage Industry: Think about high-value products. Molecular distillation is used for concentrating flavors and fragrances, extracting essential oils, removing pesticides, improving the color of edible oils, and purifying monoglycerides (emulsifiers). I had a client in France who used our equipment to refine specialty fruit extracts, achieving unparalleled aroma concentration.

Chemical Industry: For specialty chemicals, this technique is invaluable for purifying polymers, separating isomers, refining waxes and resins, and processing lubricating oils. It can handle high-viscosity materials that are difficult for other distillation methods.

Cosmetics & Personal Care: The demand for high-purity natural ingredients is growing. Molecular distillation is used to extract and refine active components from botanicals, purify lanolin, concentrate essential oils, and improve the quality of cosmetic esters.

Cannabis & Hemp Processing: This is a rapidly expanding application. Molecular distillation is crucial for producing high-purity THC and CBD distillates from crude extracts, removing terpenes, pesticides, and other impurities. The demand for high-quality, clean cannabis concentrates makes this technology essential. Our equipment is well-suited for this, ensuring compliance and quality.

Research & Development: Beyond industrial scale, academic universities and research institutions use our lab-scale molecular distillation units for pioneering new applications, developing novel materials, and exploring separation science.

The common thread across all these industries is the need to process high-value, often delicate, materials where purity and minimal degradation are paramount. It allows companies to create premium products that command higher prices in the market. We've proudly supplied equipment solutions to tens of thousands of enterprises and individuals globally, and it's always rewarding to see how our technology contributes to their success.

Conclusion

Molecular distillation offers superior purification for heat-sensitive materials. As an experienced global manufacturer, we are here to help you select the ideal system for your needs.