Struggling to take your lab-scale separations to the next level? Concerned about risks and costs of full-scale production? A pilot plant distillation column offers a clear solution.

A pilot plant distillation column is a key middle step. It helps you test, improve, and make your distillation processes better before you spend a lot on big-scale production. This makes sure your product is good and you work well.

When we talk about growing your chemical or pharmaceutical business, moving from the lab to full production is a big jump. It's exciting, but it can also be risky. You want to make sure your great lab results can be repeated on a larger scale, without unexpected problems. That's where I believe pilot plants, especially those with distillation columns, become so important. They are like a rehearsal before the main show.

What Makes a Pilot Plant Distillation Column Essential for Process Development?

Facing doubts about making your lab success bigger? Worried that new problems could mess up your production plans and budget? A pilot column connects the lab to the factory.

A pilot plant distillation column is very important for checking your process. It gives you key data, helps find possible issues, and lets you make things better before you go to full-scale production. This saves you time and money.

In my 16 years of experience helping companies with their lab and production equipment, I've seen firsthand how a pilot plant distillation column can be a game-changer. It’s not just about making more product; it’s about learning. You get to collect so much important data. For example, you can understand how heat moves and how liquids flow inside the column, which is often different from small lab setups. You can also test how your process handles different starting materials or small changes in what you put in. This is super useful if your raw materials might change over time. Plus, you can find the best settings for temperature, pressure, and how much liquid you return to the column (we call this reflux ratio). These settings can make a big difference in how pure your product is and how much energy you use. I remember a client in the specialty chemical sector. They were about to build a large plant. We convinced them to run a pilot phase first. They discovered that a minor component in their feed, which was not an issue in the lab, caused significant foaming in a continuous pilot column. Catching this early saved them a huge amount of money and redesign time. It also gives your team a chance to get trained on running the equipment before the big plant is ready.

How Does Molecular Distillation Fit into Pilot Plant Setups for High-Value Products?

Dealing with materials that spoil with heat or are very heavy? Is normal distillation not good enough for your valuable products? Molecular distillation system at pilot scale might be your answer.

For cleaning things that are sensitive to heat, a molecular distillation system is great in a pilot plant. It works with strong vacuum and materials pass through quickly. This stops heat damage and makes products very pure.

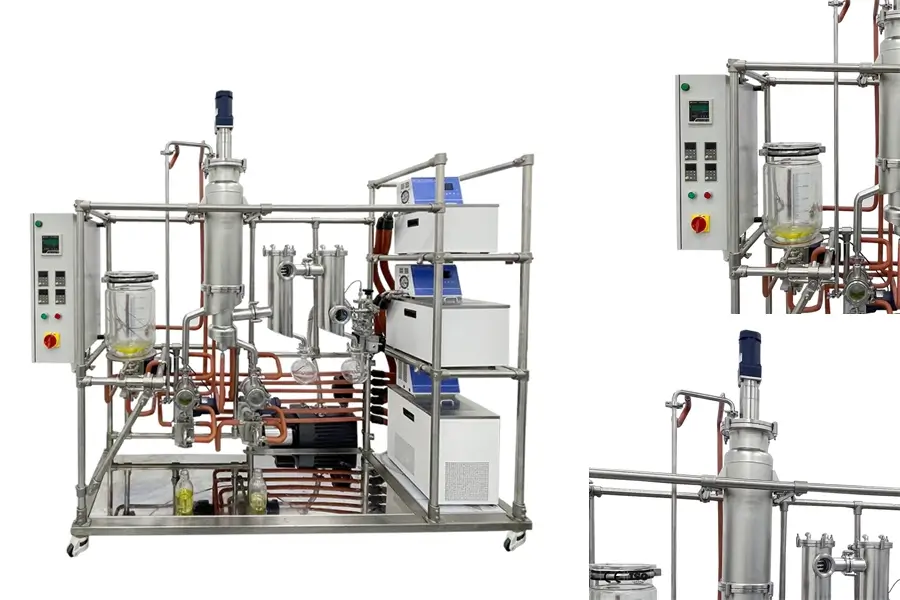

Molecular distillation is a special technique, and it’s one we at ZZKD are experts in, especially with our wiped film molecular distillation units. It's perfect for materials that can't handle high temperatures for long, like many natural oils, pharmaceutical ingredients, or specialty polymers. The magic happens because it uses a very high vacuum and the material only stays hot for a very short time. This is why it's often called short path distillation. In a pilot plant, using molecular distillation lets you fine-tune these critical conditions. You can experiment to find the perfect vacuum level, the best feed rate, and the ideal temperatures for both evaporation and condensation. These factors are crucial when you're dealing with delicate, high-value compounds. For instance, in the fish oil industry, achieving high concentrations of EPA and DHA without damaging them is key. A pilot-scale short path molecular distillation unit allows producers to perfect this process. We’ve worked with many clients, from those extracting CBD to those purifying vitamin E, and seeing them achieve incredible purity with pilot-scale molecular distillation is always rewarding. It really bridges the gap to successful, high-quality production.

What are the Key Design and Operational Considerations for a Successful Pilot Distillation Column?

Worried your pilot plant won't give you the results you hope for? Not sure about important design choices that affect how well it works? Good planning is the secret to pilot success.

Getting good results from a pilot distillation column depends on smart design and careful operation. Important things are choosing the right materials, the parts inside the column, automatic controls, and safety systems, all matched to what your process needs.

Building and running a successful pilot distillation column involves more than just making a smaller version of a big one. As a molecular distiller and equipment manufacturer, we pay close attention to these details. There are several key things you must think about.

Material Selection: What Should Your Column Be Made Of?

The material you choose for your column and its parts is very important. It needs to resist any corrosion from the chemicals you are using. It also has to handle the temperatures and pressures of your process. For many lab and pilot setups, especially when you need to see what’s happening inside, glass is a great choice. We make a lot of glass reactors and evaporators. But if you have higher pressures or temperatures, or if glass is not compatible, stainless steel is often used. We always advise our clients to think carefully about this. A personal story I recall is a startup working with a very acidic compound. They initially considered a cheaper material for their pilot column to save costs. We showed them data on corrosion rates, and they wisely opted for a more resistant alloy. It cost more upfront, but saved them from a potential failure and costly downtime later.

Column Internals: Packed or Trays?

Inside the column, you'll have either packing material or trays. These are what make the separation happen by creating surfaces for vapor and liquid to meet. Packed columns are often simpler and good for vacuum operations or when you need low liquid hold-up. Tray columns can sometimes handle larger volumes or dirtier feeds better. The choice depends on what you want to achieve – how pure your product needs to be and how much you need to process. We help customers choose the right type and size of packing or trays for their specific molecular distillation equipment needs.

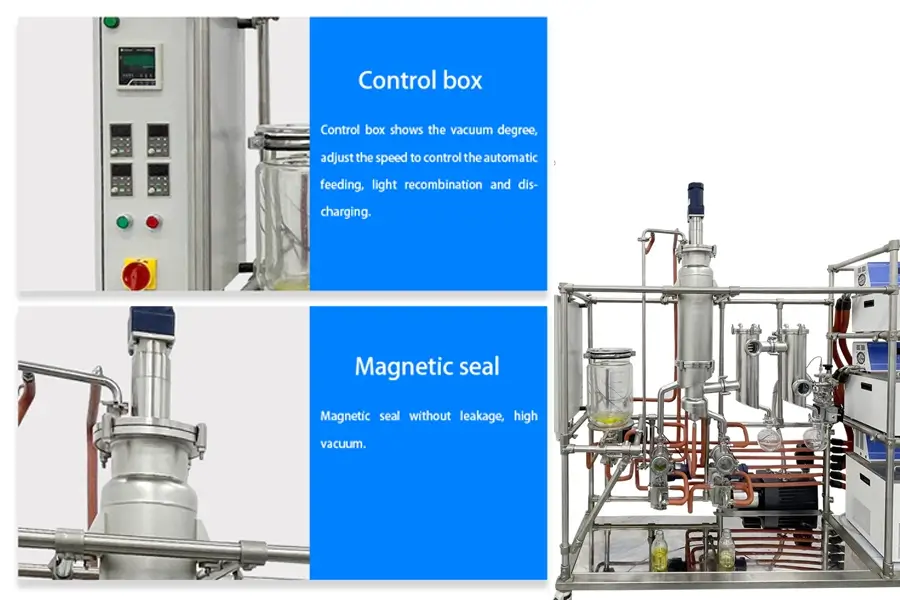

Instrumentation and Automation: How Smart Should Your Pilot Plant Be?

Good instruments are like the eyes and ears of your pilot plant. You need sensors to measure temperature, pressure, and flow rates accurately. Having a good control system, maybe even automated, helps keep the column running smoothly and gives you reliable data. In my early days, I saw a company try to run a complex pilot distillation manually. Their results were all over the place because it was hard to keep conditions steady. Investing in good automation really pays off in consistent results and less work for your operators.

| Consideration | Why it's Important for Pilot Scale | Example |

|---|---|---|

| Material Compatibility | Prevents corrosion, ensures product purity, safety. | Using Hastelloy for highly corrosive acids instead of standard stainless steel. |

| Column Diameter & Height | Impacts throughput, separation efficiency, and scalability. | Choosing a diameter that allows for testing different flow rates. |

| Type of Internals (Packing/Trays) | Affects efficiency, pressure drop, and liquid holdup. | Structured packing for high efficiency and low pressure drop in vacuum distillation. |

| Reboiler & Condenser Sizing | Ensures adequate heat input and vapor condensation. | Sizing the reboiler for maximum expected boil-up rate. |

| Control System & Instrumentation | Allows for stable operation, data logging, and process optimization. | Automated reflux ratio control to maintain product quality. |

| Safety Features | Protects personnel and equipment. | Pressure relief valves, emergency shutdown systems. |

Thinking through these aspects carefully will make your pilot plant a valuable tool, not a source of frustration. We always tell our clients: plan your pilot plant like you would plan your full-scale facility, just smaller.

Conclusion

A pilot plant distillation column is a smart step for scaling up. It helps you test, learn, and ensure your big production is successful and efficient for your valuable products.