Are you finding it hard to get the super pure products you need? Old methods can be slow and not very good. This can really affect your work and results.

High purity distillation, especially advanced methods like molecular distillation, helps you get very pure substances. It does this by carefully separating parts of a mixture based on their boiling points, even for sensitive materials. This means better quality and often more product.

As a company that has been making and sending lab equipment all over the world for over 16 years, we have seen how much the right distillation method matters. We want to help you understand these techniques better. Let's look at how you can get the best purity for your products.

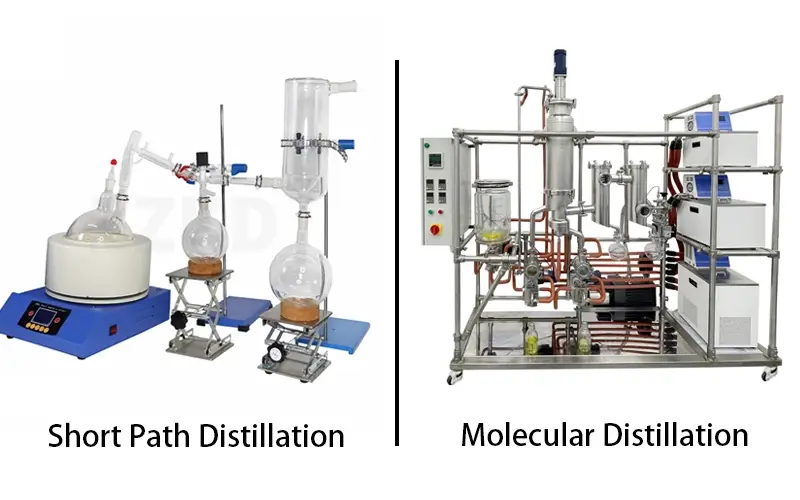

What Makes Short Path Molecular Distillation a Game-Changer for Purity?

Struggling with materials that get damaged by heat? Worried about your product breaking down during separation? Getting super high purity can be a real challenge with these tricky substances.

Short path molecular distillation is great because it reduces heat stress by working under a high vacuum. This lets you separate compounds with high molecular weights at lower temperatures. This gives you top purity and more of your product.

The main idea behind short path distillation is simple but very effective. The substance you are distilling only travels a very short distance between the hot surface where it evaporates and the cool surface where it turns back into a liquid. This happens in a strong vacuum. Why is this so good? Traditional methods often heat materials for too long or at too high temperatures. This can break down sensitive compounds. I remember when we first helped a client in the essential oils business. They were losing many of their valuable scent compounds with their old distillation setup. When they switched to one of our molecular distillation systems, it was a totally different story for them. They could finally get the pure, undamaged oils they needed. The short exposure time to heat is key. This method is perfect for materials that are sensitive to heat, have a high boiling point, or are very thick.

Key Advantages Over Traditional Methods

Lower Temperatures: Protects delicate, heat-sensitive compounds from degrading.

Reduced Thermal Stress: The short exposure time minimizes the risk of unwanted chemical reactions.

Higher Purity: Achieves better separation for complex mixtures.

This technique truly is a step up if you are serious about purity and quality, especially for high-value products. It often means fewer steps to get the final pure product too.

Are Conventional Distillation Methods Limiting Your Lab's Potential?

Are your old distillation methods slowing things down? Are you frustrated by getting low amounts of product or products that are not pure enough? Your current setup might be holding you back.

Old-style distillation can have trouble with complex mixes, heat-sensitive stuff, or compounds that boil at very high temperatures. This often means you don't get full separation, your product gets damaged, or you have to distill it many times.

Many labs still use simple or fractional distillation. These methods are fine for some easy separations. But they have big limits. For example, some mixtures form something called an azeotrope, where the mix boils at a constant temperature, making it very hard to separate further with simple distillation. Also, many valuable natural products or specialty chemicals can break down if they get too hot for too long. We often see labs trying to purify natural extracts with equipment that is not really made for such careful jobs. It’s like trying to use a big hammer for a tiny screw – it might sort of work, but it’s not the best way and can cause damage. Even vacuum distillation, which is an improvement because it lowers boiling points, has its own limits when you are dealing with very sensitive or very high boiling point materials. These limits can directly affect your results, especially in industries like pharmaceuticals where you might need 99.9% purity, or in food and fragrance where even tiny impurities can change the taste or smell.

Common Problems with Older Methods:

Incomplete separation of components.

Thermal degradation of valuable products.

Lower yields than expected.

Need for multiple, time-consuming distillation runs.

If you're facing these issues, it's probably time to look at more advanced distillation technologies that we, as an experienced molecular distiller manufacturer, specialize in.

How Does a Wiped Film Molecular Distillation System Actually Achieve Such High Separation?

Are you confused about how these advanced distillation machines work? Do you need to separate thick or sticky materials that easily cause fouling? Understanding how it works is important.

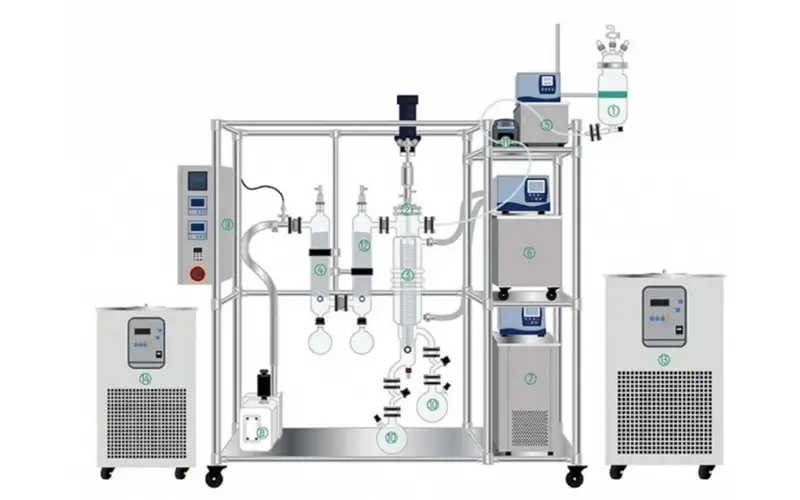

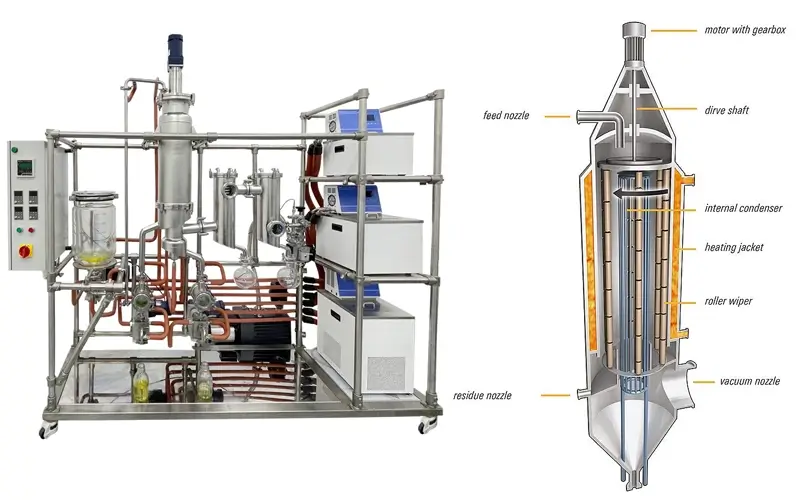

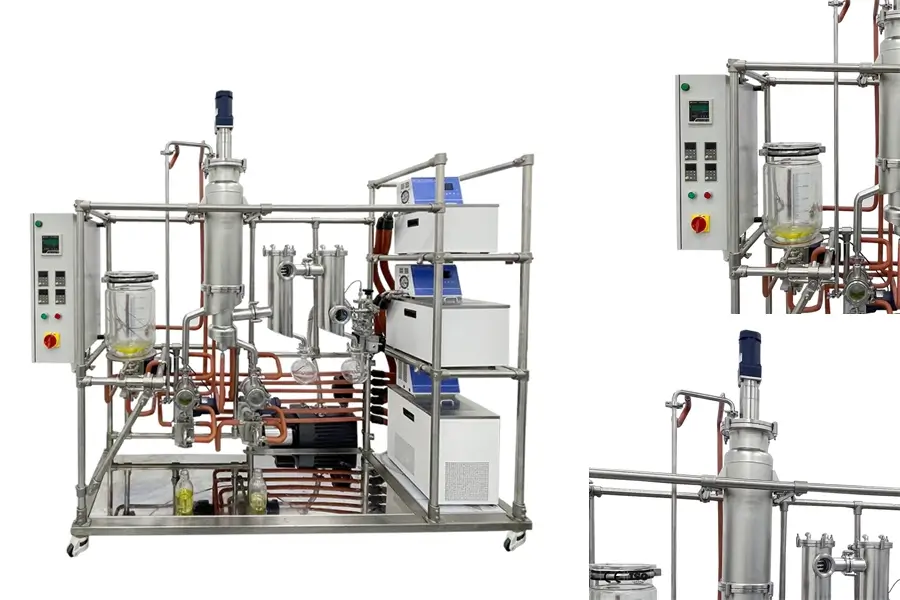

A wiped film molecular distillation system uses turning wipers. These wipers spread your material into a very thin, moving film on a heated surface. This helps heat and material move better under strong vacuum conditions.

Let me explain how a wiped film evaporator, a key part of these systems, works. First, your raw material is fed into the unit. Inside, there's a heated cylinder. Rotating wipers spread this material into a very thin film on the inner wall of this cylinder. Because the film is so thin and constantly mixed by the wipers, heat moves into it very quickly and efficiently. This causes the more volatile parts (the ones that evaporate easily) to turn into vapor. This all happens under a very strong vacuum. This vacuum is important because it lowers the boiling temperature needed and helps the vapor molecules move freely. Right in the middle of the cylinder, there's a condenser – a cool surface. The vapor molecules travel a very short distance to this condenser and turn back into liquid. This liquid is your purified product, and it's collected separately from the less volatile material that flows down the heated wall. One of our clients processing fish oils needed to separate Omega-3 fatty acids without damaging them. Our wiped film evaporator was the perfect solution because it could handle the thick oil and its heat sensitivity. The continuous wiping action also helps prevent material from building up or burning on the heated surface, which is great for materials that tend to foul.

Key Features of Wiped Film Systems:

Efficient for viscous and heat-sensitive materials.

Minimizes fouling on the heating surface.

Short contact time with heat.

Can often be run continuously for higher throughput.

Which Industries Gain the Most from Investing in Advanced Molecular Distillation Equipment?

Are you wondering if molecular distillation is the right choice for your type of work? Not sure how it could be used for your specific products? Many different fields are getting great benefits.

Industries like making medicines, health supplements, food and drinks, chemicals, and processing cannabis benefit a lot. They use it to purify, concentrate, and get valuable compounds where quality is super important.

We've provided our molecular distillation equipment to a wide range of industries, and it's amazing to see the different ways they use it. In the pharmaceutical world, it's all about purity. Our systems help make active pharmaceutical ingredients (APIs) super pure and remove tiny unwanted bits. For nutraceuticals and food processing, it’s often used to get valuable things like vitamins (think Vitamin E), essential oils, Omega-3s from fish oil, or to make flavors and colors stronger and purer. In the chemical industry, companies use it to purify special chemicals, like monomers before they make polymers, or to clean up solvents. The cannabis industry has really taken to molecular distillation. It's key for making high-purity THC and CBD distillates from crude extracts. Even cosmetics companies use it to refine plant extracts and special oils for their products. We once equipped a university research team with one of our systems. They were working on isolating a new compound from a rare plant that could have health benefits. The precision of our equipment was crucial for their breakthrough. The common thread is the need for high purity and careful handling of valuable or sensitive materials.

Examples of Applications:

| Industry | Common Applications |

|---|---|

| Pharmaceuticals | API purification, impurity removal, solvent stripping |

| Nutraceuticals/Food | Vitamin E concentration, Omega-3 purification, essential oil extraction, flavor concentration |

| Chemicals | Monomer purification, specialty chemical refining, solvent recycling |

| Cannabis Processing | THC/CBD distillation, terpene separation, winterization refinement |

| Cosmetics | Botanical extract refinement, purification of active ingredients |

How Do You Select the Ideal Molecular Distillation System for Your Specific Needs?

Feeling lost with all the equipment choices out there? Not sure which features are most important for what you do? Picking the right one is very important for your success.

Think about what your material is like (how thick, how sensitive to heat, its boiling point). Also consider the purity you want, how much you need to process, and if you might need to process more later. Talking to experienced makers like us can really help guide you.

Choosing the right molecular distillation system is a big decision. I always tell our potential clients, "Don't just buy a machine, buy a solution that fits your problem." We had a startup company that almost bought a much larger system than they needed. After we talked about their current needs and their plans for growth, we suggested a smaller, modular system. This saved them a lot of money upfront and also space in their lab, while still giving them room to grow. So, what should you think about?

Key Factors for Selection:

Material Properties:

Volatility: How easily does it evaporate?

Thermal Stability: Can it handle heat, or does it break down easily?

Viscosity: How thick is it? This affects how well it flows and forms a film.

Fouling Tendency: Does it tend to stick or burn on hot surfaces?

Process Requirements:

Desired Purity: What level of purity do you need for your final product?

Throughput: How much material do you need to process per hour or per day? (Lab scale, pilot scale, or full production?)

Batch or Continuous: Do you process in separate batches, or do you need a continuous flow?

Equipment Features:

Evaporator Type: Different designs like short path, wiped film, or even falling film evaporators work best for different materials. For example, a falling film evaporator can be great for less viscous materials and high evaporation rates.

Vacuum System: How strong a vacuum can it achieve and maintain? This is critical.

Temperature Control: How precisely can you control the heating and cooling?

Material of Construction: Usually stainless steel or glass, depending on chemical compatibility and visibility needs.

Support and Service: What kind of help can you get after you buy it? Are spare parts easy to get? As a company that exports worldwide, we know how important our 24/7 after-sales support is to our customers.

Thinking carefully about these points will help you pick a system that works well for you now and in the future.

Conclusion

Choosing the right high purity distillation technique, especially molecular distillation, can greatly improve your product quality and efficiency. We are here to help you succeed.