Struggling to get truly pure CBD isolate? Finding current methods too complex or not effective enough? You are not alone in this challenge.

Yes, short path distillation is an excellent method for refining CBD oil to high purity levels. It effectively separates cannabinoids, like CBD, from terpenes, lipids, and other less desirable compounds. My company has helped many clients achieve remarkable purity with this technology.

I understand that navigating the world of CBD extraction and purification can be complex. As a manufacturer of laboratory and industrial equipment for over 16 years, I've seen the evolution of these processes firsthand. Short path distillation, especially, stands out for its efficiency in creating high-quality CBD products. This method is a cornerstone of modern CBD processing, and it's something we specialize in. Let's explore why this technique is so vital for anyone serious about producing top-tier CBD. Many of our customers ask about a complete molecular distillation system for this purpose.

How Exactly Does Short Path Distillation Purify CBD Oil?

Wondering how this scientific process actually cleans up your CBD? Are the technical details a bit hazy? Let me shed some light on it.

Short path distillation purifies CBD oil by separating compounds based on their different boiling points under deep vacuum. The crude CBD oil is heated, and desired compounds like CBD vaporize, travel a short distance, and then condense on a chilled surface, leaving heavier impurities behind.

Let me break this down further for you. Imagine you have a mix of different substances in your crude CBD extract. Each substance has a unique temperature at which it turns into a vapor. Short path distillation takes advantage of this property. Here's what we often explain to our clients:

The Core Principle: Vacuum and Temperature

The "short path" part is crucial. It means the vaporized CBD molecules only travel a very short distance – usually just a few centimeters – before they hit a condenser. This is done inside a system that's under a strong vacuum. Why the vacuum? A vacuum lowers the boiling points of all the compounds. This is great because it means we don't have to heat the CBD oil to very high temperatures, which could damage the CBD. Lower temperatures mean better quality. I remember a client who was struggling with product degradation; switching to a proper short path molecular distillation setup solved their issue.

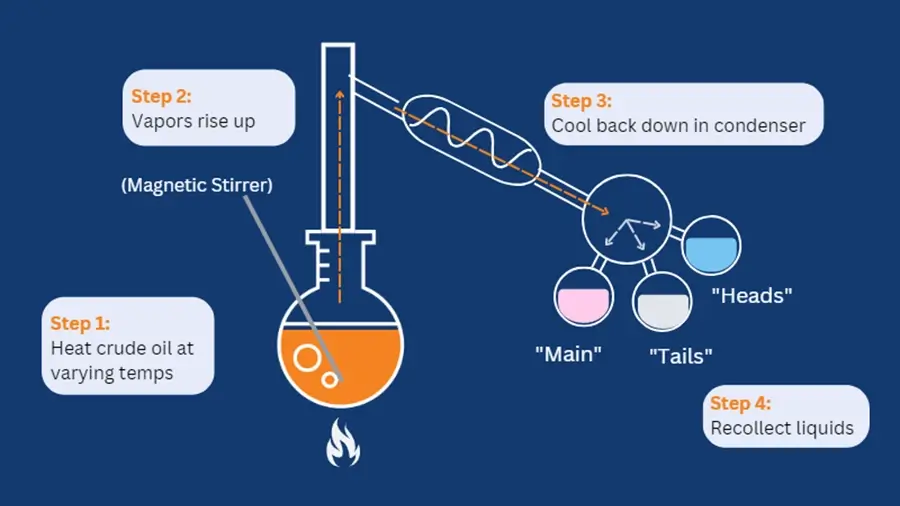

Step-by-Step Separation

1. Feeding: Crude oil is fed into the heated evaporator body.

2. Evaporation: As the oil spreads thinly on the heated surface (often by a wiper mechanism in a wiped film molecular distillation unit), the more volatile compounds (like terpenes, if not already removed, and then CBD) begin to vaporize.

3. Short Travel & Condensation: These vapors rise and quickly meet the internal condenser, which is cooled. The CBD vapor turns back into a liquid and is collected.

4. Residue Collection: Heavier compounds, like waxes, chlorophyll, and other plant matter, don't vaporize as easily at these temperatures and vacuum levels. They are collected separately as residue.

This process can be run multiple times (passes) to achieve even higher purity. My experience shows that understanding these steps helps operators optimize their yields and purity effectively.

What Advantages Does Short Path Distillation Offer for CBD Production?

You're considering different purification methods, right? Feeling overwhelmed by choices and wondering if short path is truly better? I can help clarify the benefits.

Short path distillation offers significant advantages for CBD production, including achieving high purity (often 90%+), preserving thermally sensitive compounds like CBD due to low operating temperatures and short residence times, and efficient separation of cannabinoids from undesirable contaminants.

From my 16 years in this industry, I've seen many techniques, but for CBD, short path distillation, a type of molecular distillation, truly shines. Let's look at why it's a preferred method for so many serious CBD producers we work with:

Key Benefits We've Observed:

High Purity Achievable: This is the big one. Short path distillation can consistently produce CBD distillate with purities exceeding 90%, and sometimes even up to 99% after multiple passes. This is crucial for products like isolates or high-potency oils.

Gentle on CBD: CBD is sensitive to heat. The combination of deep vacuum (lowering boiling points) and the short heating time (short residence time of the oil on the hot surface) minimizes the risk of thermal degradation. This means you preserve more of the valuable CBD. I recall a research institute we supplied equipment to; they specifically chose our systems for this reason, to protect delicate cannabinoids.

Effective Removal of Contaminants: It's excellent at separating CBD from things you don't want: chlorophyll, waxes, lipids, pesticides (if they have different boiling points), and even some terpenes if you're aiming for a flavorless, odorless distillate.

Scalability: While we offer lab-scale units for R&D, the principles of short path distillation scale up to industrial production levels. We've helped companies grow from small setups to larger operations using this technology. The molecular distillation price can vary based on scale, but the ROI is often very good due to product quality.

Comparison with Other Methods

Compared to simpler methods like winterization or basic filtration, short path distillation provides a much finer degree of separation. While chromatography can achieve very high purity, it's often more complex and expensive for bulk purification than distillation. For many, distillation offers the best balance of purity, efficiency, and cost, especially when processing larger volumes for the market.

What Should You Look For in a CBD Short Path Distillation System?

Ready to invest but unsure what features really matter in a system? Worried about making the wrong choice for your specific CBD production needs? I'll guide you through it.

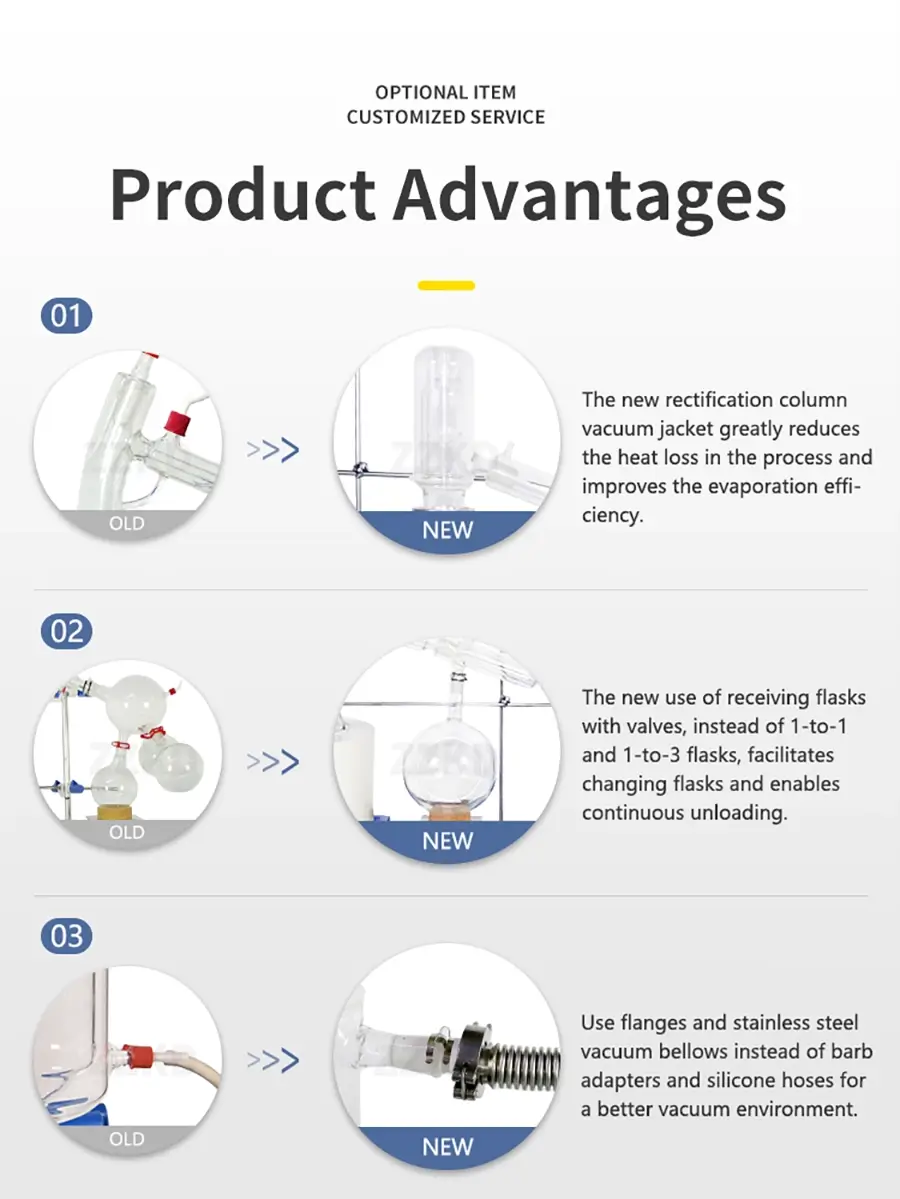

When choosing a CBD short path distillation system, look for appropriate material quality (like borosilicate glass or stainless steel), an efficient vacuum pump capable of deep vacuum, precise temperature control for both the evaporator and condenser, and a design that is easy to operate and maintain.

Selecting the right molecular distillation equipment is a critical decision. As a manufacturer, we always advise our clients to consider several key factors to ensure they get a system that meets their needs and provides long-term value. It's not just about the initial purchase; it's about performance, reliability, and support.

Essential System Components and Considerations:

| Component/Feature | Why It's Important for CBD Distillation | What We Recommend |

|---|---|---|

| Evaporator Material & Design | Needs to withstand thermal stress and be non-reactive. Efficient heat transfer is key. | Borosilicate glass 3.3 for visibility and lab scale. Stainless steel for larger, industrial scale. Wiped film designs enhance efficiency. |

| Vacuum Pump | Crucial for lowering boiling points and enabling molecular distillation. | A two-stage rotary vane pump paired with a diffusion pump or turbomolecular pump to achieve deep vacuum levels (e.g., 0.001 mbar). |

| Condenser | Efficiently liquefies the CBD vapor. Temperature control is vital. | Internal condenser with a large surface area. Must be paired with a chiller capable of maintaining stable, low temperatures. |

| Temperature Control | Precise heating of the feed and cooling of the condenser are essential for separation. | Digital PID controllers for heating mantles/jackets and chillers. Accuracy and stability are paramount. |

| Feed & Discharge Systems | Continuous or batch feeding, and separate collection of distillate and residue. | Gear pumps for continuous feed on larger systems. Properly designed collection flasks or receivers that maintain vacuum. |

| Ease of Use & Maintenance | Simplifies operation, reduces downtime, and ensures consistent results. | Systems with clear visibility (glass parts), easy-to-access components, and straightforward cleaning procedures. Good documentation and support from the molecular distiller manufacturer are also key. |

I always tell my clients, "Don't just look at the price." Consider the quality of components, the precision of control, and the after-sales support. A slightly higher initial investment in a quality system often pays off quickly through better yields, higher purity, and less downtime. My team and I have spent years refining our designs to meet these very needs for CBD processors globally.

In summary, short path distillation is a powerful tool for producing high-purity CBD, offering clear advantages. Choosing the right system involves careful consideration of its components and your specific production goals.