Want to create pure essential oils? Struggling with complex setups? A small distiller might be your simple solution to start your aromatic journey with us.

A small-scale essential oil distiller is compact equipment designed for extracting essential oils from plant materials through methods like steam or hydrodistillation. It is ideal for hobbyists, small businesses, or initial research, offering a straightforward way to produce high-quality oils right from your own space.

Starting with essential oil distillation can seem daunting. But, I want to assure you it's a rewarding process. We, as a company, have seen many individuals and small businesses begin this way. They explore the wonderful world of aromas and natural products. Let's look at what these distillers are.

What Exactly is a Small-Scale Essential Oil Distiller?

Feeling curious about what makes up these compact extractors? Perhaps you wonder how they fit into smaller operations or labs like yours. Let's clarify this for you.

A small-scale essential oil distiller is a complete, usually portable, system. It includes a boiler for steam, a chamber for plant material, a condenser to cool vapor, and a separator for oil and water. Sizes typically range from a few liters to around 50 liters.

When we talk about small-scale essential oil distillers, we are referring to equipment designed for ease of use and for processing smaller batches of plant material. I remember when we first started helping clients with these; they were often amazed at how accessible distillation could be. These units are quite different from large industrial setups, which require significant space and investment. For someone starting out, or for a lab needing to test various botanicals, a small distiller is perfect.

Key Components You'll Typically Find:

Still Pot (Biomass Chamber): This is where you place your plant material. It needs to be made of non-reactive material, often stainless steel or sometimes copper for specific traditional reasons.

Heat Source: This could be an integrated electric heater, a gas burner, or an induction cooktop placed underneath the still pot. Control over temperature is important.

Condenser: After the steam carries the volatile oils from the plant, it needs to be cooled back into liquid form. Condensers can be worm-type (coiled tube in a water bath) or Liebig (straight tube with a water jacket).

Separator (Essencier): Once condensed, the mixture of essential oil and hydrosol (floral water) needs to be separated. The separator uses the principle that oil and water don't mix and have different densities.

These systems are often designed as all-in-one units, making setup simpler. We've seen them used in kitchens, small workshops, and university research labs. Their compact nature means they don't demand a dedicated facility, which is a big plus for many of our customers. The goal is to make essential oil extraction available to a wider audience, and these small distillers achieve that beautifully.

How Does Small-Scale Essential Oil Distillation Work?

Is the process of extracting oils with a small distiller a mystery to you? Concerned it might be too scientific or complex for your setup? Let me simplify it.

Small-scale distillation usually uses steam. Steam passes through plant material, carrying volatile oils. This vapor is cooled in a condenser, turning back to liquid. The oil then separates from the water, ready for collection. It’s a gentle and effective method for many botanicals.

The most common method you'll encounter with small-scale distillers is steam distillation. It sounds technical, but the principle is straightforward. I like to explain it as giving the plants a "steam bath" that coaxes out their aromatic treasures. We have guided countless clients through their first distillations, and it's always a joy to see their excitement.

Here's a Simple Breakdown of the Steam Distillation Process:

Water Boils: Water in the still pot (or a separate steam generator) is heated to produce steam.

Steam Passes Through Plants: The steam rises and passes through the plant material held in a basket or chamber above the water. The heat of the steam causes the tiny pockets of essential oil in the plant to burst open and release the volatile aromatic compounds.

Oil Vaporizes: These volatile compounds evaporate and mix with the steam.

Vapor Travels to Condenser: The mixture of steam and oil vapor travels through a connecting pipe to the condenser.

Condensation: The condenser is cooled, usually by circulating cold water. As the vapor cools, it turns back into a liquid mixture of water (now called hydrosol or floral water) and essential oil.

Separation: This liquid mixture flows into a separator. Because oil and water don't mix and usually have different densities (most essential oils are lighter than water), they form distinct layers. The essential oil can then be carefully decanted or siphoned off.

Hydrodistillation is another method where plant material is directly immersed in water, which is then boiled. This is sometimes used for delicate flowers or powders. But for most common essential oils like lavender, peppermint, or eucalyptus, steam distillation is preferred in these small setups. It’s efficient and helps prevent scorching the plant material.

What Are the Benefits of Using a Small-Scale Distiller for Essential Oils?

Wondering if investing in a small distiller is worth it for your goals? Doubting if it can truly deliver quality or be practical for you? Let's explore the advantages.

Small-scale distillers offer control over oil quality and freshness. They are cost-effective for small batches, allow experimentation with various plants, and provide educational value. Plus, you get both essential oil and valuable hydrosol as a co-product. They empower you to create unique products.

From our experience as a manufacturer, we see many reasons why people choose small-scale distillers. It's not just about the size; it's about the possibilities they open up. One of our customers, a small artisan soap maker, started with a small distiller to create unique scents for her products. She told me it transformed her business.

Key Advantages We've Observed:

Quality Control: You know exactly what plant material is going in, how it was grown (if you grow it yourself), and the exact process used. This gives you unparalleled control over the purity and quality of your essential oils.

Freshness: Commercially available oils can sit on shelves for a long time. Distilling your own means you get the freshest possible oils, which often have a more vibrant aroma.

Cost-Effectiveness for Small Batches: If you only need small quantities of oil or want to experiment with many different plants, a small distiller is much more economical than buying many different commercial oils or investing in large equipment. You can check various molecular distillation price points for advanced systems to see the difference for larger scales.

Experimentation and Learning: These units are fantastic for learning the art and science of distillation. You can try different plants, vary distillation times, and truly understand the process.

Production of Hydrosols: The co-product of distillation, the hydrosol (floral water), is a valuable product in itself. It can be used in cosmetics, as a room spray, or for skincare.

Sustainability: If you grow your own plants or source them locally, you can create a very sustainable product with a low carbon footprint.

For small businesses, this means creating signature scents or therapeutic blends. For hobbyists, it's the joy of creation and connecting with nature. For researchers, it's a practical tool for preliminary studies. The versatility is a major draw. We've even seen culinary enthusiasts use them for extracting unique food flavorings!

When Might I Need More Advanced Distillation, Like a Molecular Distillation System?

Is your small distiller meeting all your needs, or do you find some oils are tricky to extract or purify? Wondering if there's a next level for specific applications? This is an important consideration.

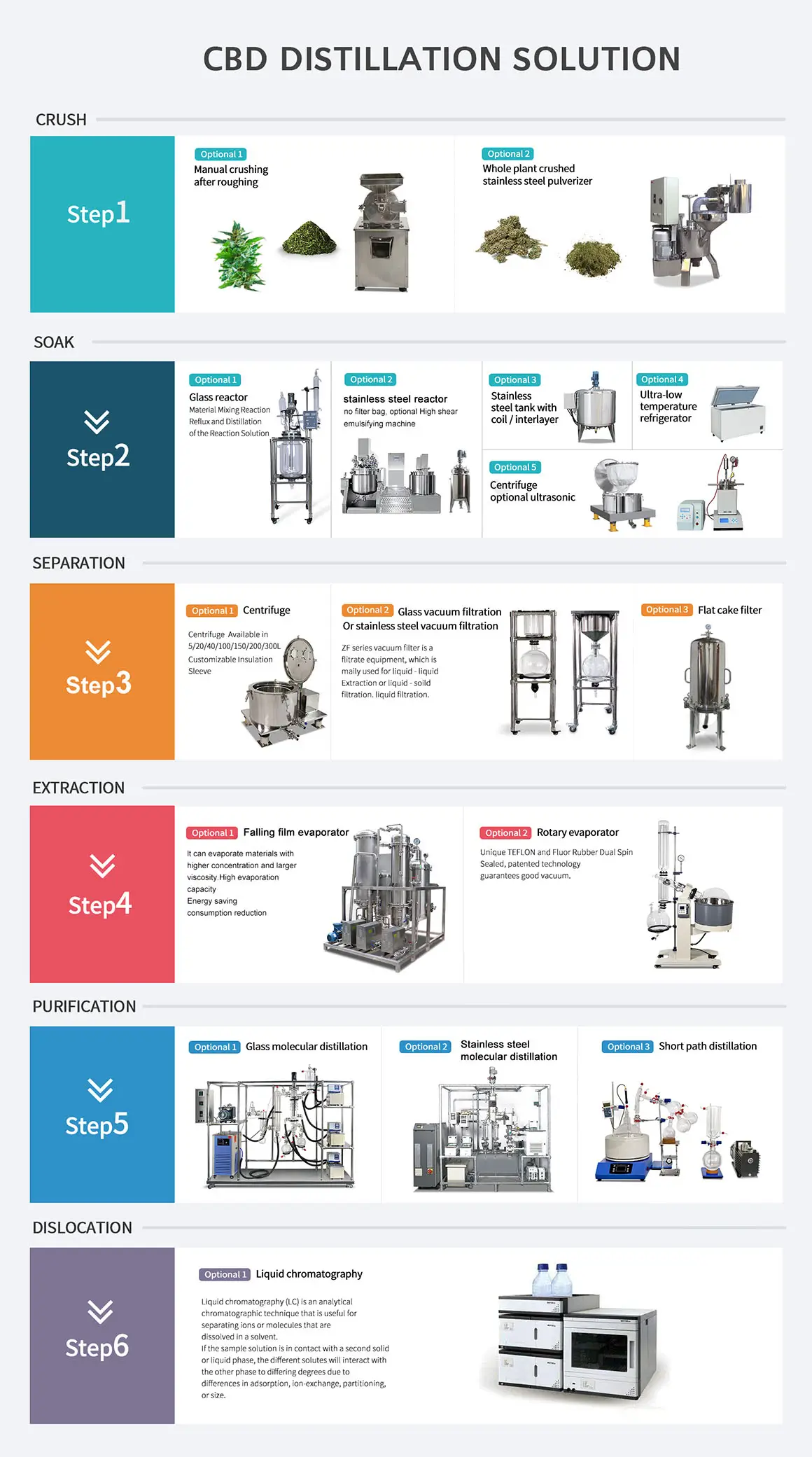

For heat-sensitive oils, high-purity separations, or processing viscous materials, basic steam distillation may not be enough. Advanced methods like a molecular distillation system offer solutions for these challenges, especially in refining valuable compounds or for specific industrial applications.

While small-scale steam distillers are fantastic for many essential oils, there are situations where more specialized technology is needed. As a molecular distiller manufacturer, we often help clients who are looking to upgrade or tackle more complex purification tasks. For instance, some essential oils contain very delicate compounds that can be damaged by the prolonged heat of steam distillation. Or, you might want to isolate a specific molecule from an essential oil for pharmaceutical or flavor applications.

Consider Advanced Distillation If:

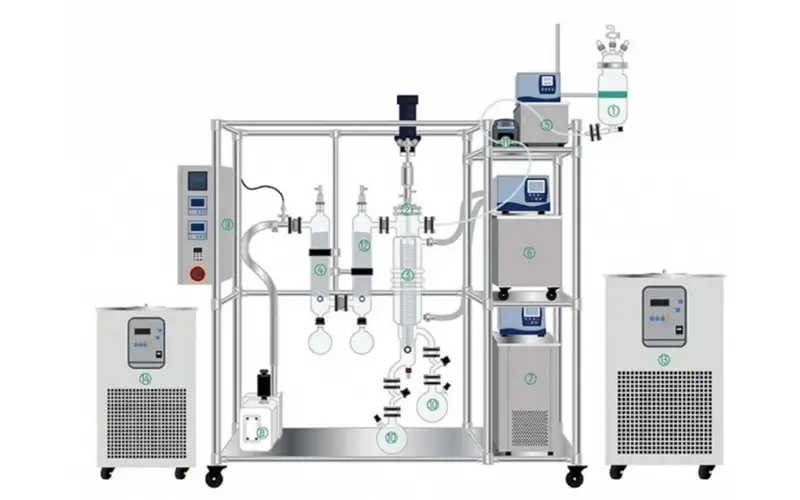

You handle heat-sensitive materials: Some valuable botanical compounds degrade easily with heat. Technologies like short path molecular distillation operate under high vacuum, significantly lowering the boiling point and reducing thermal stress. This is crucial for preserving the integrity of delicate molecules.

You need very high purity: If you need to separate compounds with very close boiling points or remove trace impurities to achieve pharmaceutical or food-grade standards, advanced systems offer much finer separation capabilities.

You are processing viscous or high molecular weight materials: Traditional distillation can struggle with thick, sticky substances. Wiped film evaporators, often part of a wiped film molecular distillation setup, are designed to handle these materials efficiently by creating a thin film on a heated surface.

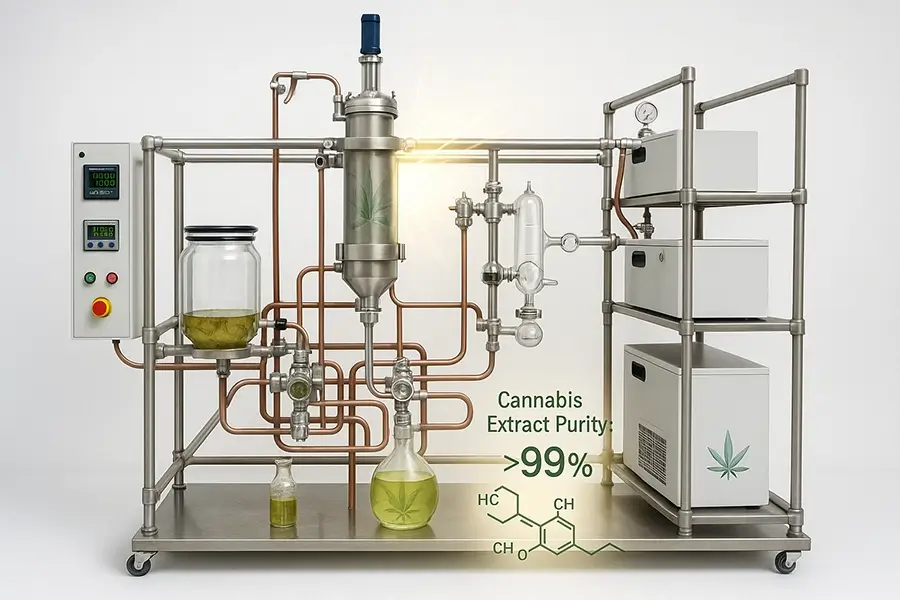

You want to isolate specific fractions: Molecular distillation excels at separating different components of a mixture based on their molecular weights, allowing for the isolation of specific desired compounds. This is common in the cannabis industry for THC/CBD isolation or in fine chemical production.

We've worked with clients who started with basic essential oil extraction and then moved into refining those oils or extracting specific valuable phytochemicals. For them, understanding the principles of steam distillation was a great foundation before exploring molecular distillation. It’s about choosing the right tool for the job. If your goals involve very high purity, dealing with challenging materials, or scaling up specialized extractions, then exploring advanced distillation techniques is a logical next step.

How Do I Choose the Right Small-Scale Distiller for My Needs?

Feeling overwhelmed by options? Unsure what features are critical versus nice-to-haves for your specific purpose? Let's break down the key factors to guide your decision.

Choose a distiller based on material (stainless steel is common, copper for some traditions), capacity matching your batch size, a controllable heat source, an efficient condenser, and your budget. Consider ease of cleaning and supplier support too. Prioritize safety and durability for long-term use.

Selecting your first or next small-scale distiller is an exciting step. As a company that has been in the laboratory equipment field for over 16 years, we always advise customers to think carefully about their primary goals. I once helped a client who bought a very small distiller, only to realize a month later that their herb garden produced far more material than it could handle. Planning ahead saves time and money.

Key Factors to Consider:

| Factor | Consideration | Why It Matters |

|---|---|---|

| Material | Stainless steel (304 or 316 grade) is common, durable, and non-reactive. Copper is traditional for some oils (e.g., for alcohols) and believed by some to improve scent, but requires more care and can react with some compounds. Glass components are good for visibility but fragile. | Ensures purity of oil, longevity of equipment, and safety. Avoid aluminum as it can react with plant compounds. |

| Capacity | How much plant material do you want to process per batch? Units range from 1-2 liters for hobbyists to 20-50 liters for small businesses. | Affects yield per run and efficiency. Too small is frustrating; too large might be inefficient for small plant quantities. |

| Heat Source | Integrated electric, external (gas burner, electric hot plate), or induction. Look for good temperature control. | Consistent and controllable heat is key for efficient distillation and preventing overheating or burning of plant material. |

| Condenser Type & Size | Worm, Liebig, or Graham. Needs to be efficient enough to cool all the steam produced. Sufficient cooling water flow is essential. | An inefficient condenser leads to loss of valuable vapor (and oil). Match condenser capacity to boiler size. |

| Ease of Use & Cleaning | How easy is it to set up, load plant material, operate, and clean afterwards? Wide openings are better for cleaning. | A complicated or hard-to-clean unit will be used less. Regular cleaning is vital for pure oils. |

| Budget | Prices can vary widely based on size, material, and features. | Balance cost with quality and necessary features. Sometimes paying a bit more for durability or better design is worth it. |

| Supplier Support & Reputation | Does the supplier offer good instructions, customer service, and spare parts? Check reviews. | Helpful if you're new or encounter issues. A reliable supplier (like us at ZZKD!) ensures peace of mind. |

Think about the types of plants you'll distill most often. Delicate flowers might need a more gentle approach than hardy herbs. Also, consider your space and safety. Ensure good ventilation, especially if using an open flame. We always emphasize safety in our equipment designs and user guides. Making an informed choice will lead to many successful distillations.

Conclusion

Small distillers open up essential oil creation. Consider your needs, and for advanced purity or specific compounds, explore options like molecular distillation. We are here to help you.