Worried about impurities in your Omega-3s? Low concentrations mean fewer benefits. Discover the key to truly pure and potent fish oil.

Molecular distillation is a gentle, high-vacuum process. It effectively separates Omega-3s from contaminants like heavy metals and PCBs. This technique results in highly pure and concentrated fish oil, ensuring maximum safety and effectiveness for end-users.

As someone who has been involved in manufacturing laboratory and production equipment for over 16 years, I've seen many technologies. When it comes to Omega-3s, purity isn't just a buzzword; it's the foundation of a quality product. We all want the best for our health, and that's why I believe molecular distillation is such a vital process. Let’s explore why this technology is a game-changer for anyone serious about Omega-3 quality.

Why is Purity So Crucial for Omega-3 Supplements?

Contaminated supplements can pose health risks. Impure Omega-3s also offer diminished benefits. Are you confident your fish oil is genuinely clean and effective?

Purity in Omega-3 supplements means they are free from harmful substances like heavy metals (mercury, lead), PCBs, and dioxins. This ensures consumer safety and maximizes the crucial health benefits, such as heart and brain support, without introducing unwanted toxins.

When we talk about Omega-3s, we're talking about something people take to improve their health. So, it's incredibly important that these supplements are not just effective, but also safe. The oceans, where fish for oil are sourced, can unfortunately contain various contaminants.

The Hidden Dangers in Impure Fish Oil

Crude fish oil can contain several undesirable compounds. Heavy metals like mercury, lead, arsenic, and cadmium can accumulate in fish. If not removed, these can be harmful to humans, affecting the nervous system and other organs. Then there are persistent organic pollutants (POPs) like PCBs (polychlorinated biphenyls) and dioxins. These are industrial chemicals and byproducts that don't break down easily and can also build up in fish. Ingesting them can lead to a range of health issues. At our company, we always stress that the first step to a great product is understanding what you need to remove.

Oxidation: The Enemy of Freshness and Potency

Another big concern is oxidation. Omega-3 fatty acids, especially EPA and DHA, are polyunsaturated, meaning they have multiple double bonds. These double bonds make them susceptible to oxidation, which can make the oil rancid. Impurities can sometimes accelerate this oxidation process. Oxidized oils not only taste and smell bad but also lose their beneficial properties and can even introduce harmful free radicals into the body. A good purification process like molecular distillation helps remove pro-oxidants and creates a more stable final product. I remember early experiments where the difference in shelf life and sensory quality was night and day after proper purification.

Why Concentration Matters Alongside Purity

While removing harmful substances is key, purity also allows for better concentration of the beneficial Omega-3s, EPA and DHA. Once you've removed the unwanted parts, you can concentrate the good parts. This means consumers can get a higher dose of active ingredients in smaller, easier-to-take capsules. This is a significant advantage that truly pure oils can offer.

How Does Molecular Distillation Work to Purify Omega-3s?

Understanding complex science can be tough. How do we actually separate these tiny molecules? Let's look at the straightforward principles behind molecular distillation for superior Omega-3s.

Molecular distillation uses a high vacuum and a very short distance between the evaporating surface and the condenser. This allows separation based on molecular weight at significantly lower temperatures, effectively isolating Omega-3 fatty acids from lighter and heavier unwanted compounds.

Molecular distillation might sound very technical, but the core idea is quite elegant. It's a specialized type of short-path vacuum distillation. The "short path" is critical because it means molecules don't have far to travel from the hot evaporating surface to the cool condensing surface. This, combined with a very high vacuum, is what makes the process so effective and gentle.

The Principle: Separation by Molecular Weight at Low Temperatures

The high vacuum reduces the boiling point of substances. This means we can heat the fish oil to a much lower temperature than in traditional distillation. This is vital for heat-sensitive compounds like Omega-3s, which can degrade or change their structure at high temperatures. Molecules evaporate from the heated surface and travel the short distance to the condenser. Lighter molecules (like some volatile contaminants or free fatty acids if you want to remove them) will evaporate more easily. Heavier molecules (like triglycerides containing EPA and DHA) will evaporate under specific conditions, while even heavier impurities or color bodies might be left behind. The system allows for precise separation based on these differences in molecular weight and volatility. It’s a bit like a molecular sieve, but for liquids under vacuum.

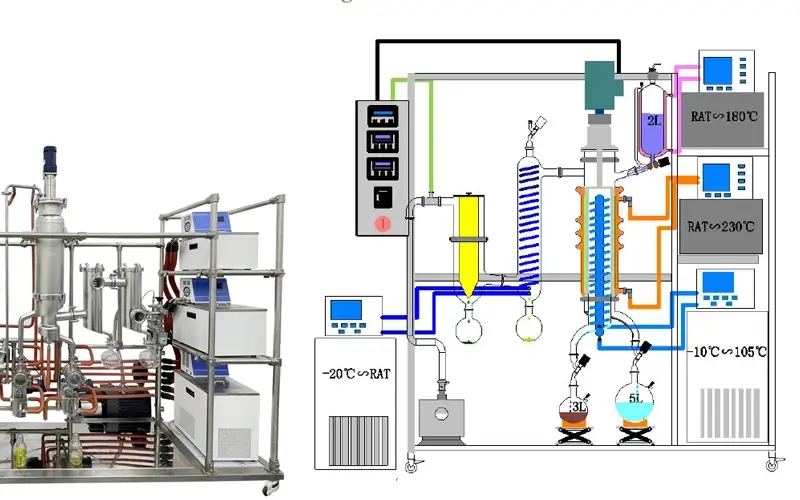

Key Components of Our Molecular Distillation Systems

As manufacturers with over 16 years of experience in exporting these systems, we've refined their design for efficiency and reliability. A typical system includes:

| Component | Function |

|---|---|

| Feeding System | Introduces the crude oil into the system at a controlled rate. |

| Evaporator | Usually a heated cylinder or surface. Our systems often use wiped film or falling film evaporators to create a thin, uniform film of oil for efficient heat transfer and evaporation. |

| Internal Condenser | Positioned very close to the evaporator. This is where the desired Omega-3 molecules condense after evaporating. |

| Vacuum System | Creates and maintains the high vacuum (low pressure) necessary for the process. This is crucial. |

| Collection Systems | Separate outlets and vessels for collecting the purified distillate (the Omega-3 rich fraction) and the residue (the fraction containing heavier impurities). |

The precision engineering of these components ensures optimal separation. We've seen our systems used worldwide, helping produce top-quality Omega-3s.

What are the Key Benefits of Using Molecular Distillation for Omega-3 Production?

Looking for higher quality Omega-3 products? Standard purification methods might not be enough. Discover the clear advantages molecular distillation offers for exceptional product quality.

Molecular distillation provides superior purity by effectively removing contaminants and undesirable odors. It allows for higher concentrations of EPA and DHA. Crucially, its gentle, low-temperature operation protects heat-sensitive Omega-3s from degradation, ensuring maximum potency and quality.

Choosing the right purification technology directly impacts the final Omega-3 product. From my experience, molecular distillation stands out for several key reasons, especially when aiming for the highest quality.

Unmatched Purity and Safety

This is perhaps the most significant benefit. Molecular distillation is exceptionally effective at removing a wide array of contaminants. This includes heavy metals like mercury, lead, and arsenic, as well as organic pollutants such as PCBs, dioxins, and pesticide residues. By reducing these harmful substances to extremely low levels, you ensure the safety of the consumer. This is something we constantly emphasize to our clients – safety first.

Higher Concentration of EPA and DHA

Beyond just removing bad stuff, molecular distillation excels at concentrating the good stuff – the valuable Omega-3 fatty acids, eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). The process can be fine-tuned to separate different fatty acid fractions, allowing for the production of oils with very high levels of EPA and/or DHA. This means a more potent product, allowing consumers to achieve desired dosages with smaller servings.

Preservation of Quality: Low Thermal Stress

Omega-3 fatty acids are very delicate and prone to heat damage. High temperatures can cause them to oxidize, break down, or form undesirable byproducts like trans fats or polymers. Because molecular distillation operates at lower temperatures and for shorter heating times (due to the thin film and short path), it minimizes this thermal stress. This helps preserve the natural structure and bioactivity of the EPA and DHA, ensuring the oil retains its full health benefits. It also leads to a product with better stability and longer shelf life.

Improved Sensory Profile

Let's be honest, nobody likes a fishy aftertaste. Molecular distillation helps remove volatile compounds that contribute to unpleasant fishy odors and flavors. This results in a much milder, cleaner-tasting oil, which greatly improves consumer acceptance. We've had clients who were amazed at the difference in the taste and smell of their oil after switching to our molecular distillation units.

How Can Our Molecular Distillation Systems Help Your Omega-3 Business?

Aiming to be a leader in the competitive Omega-3 market? Is older technology hindering your product quality? See how our advanced systems can elevate your products and strengthen your brand.

Our molecular distillation systems provide the reliability and efficiency needed to produce premium high-purity, high-concentration Omega-3s. With 16 years of focused export experience and dedicated global support, we empower you to meet stringent international quality standards and significantly enhance your product's market value.

At our company, Zhengzhou Keda Machinery and Instrument Equipment Co., Ltd. (also known as ZZKD), we don't just sell machines; we provide solutions. We've been specializing in R&D, production, and export of equipment like molecular distillation systems for over 16 years. We understand the challenges and opportunities in producing high-quality Omega-3s for the international market.

Tailored Solutions for Your Scale and Needs

Whether you are a research institution developing new formulations, a start-up entering the market, or an established company looking to upgrade your production, we have systems to match your scale. We offer everything from laboratory R&D units for small batches and process optimization to pilot-scale and full industrial-scale production systems. We also understand that one size doesn't fit all, so we offer customization options to ensure the equipment integrates perfectly into your workflow. Many of our clients appreciate our ability to adapt designs to their specific raw materials and target product specifications.

Built for Performance, Durability, and Compliance

Our equipment is designed for high performance and built to last. We use high-quality materials, often stainless steel for wetted parts, ensuring chemical resistance and ease of cleaning. Our designs focus on maximizing separation efficiency, minimizing processing times, and ensuring ease of operation and maintenance. Importantly, our products come with ISO9001 and CE certifications, demonstrating our commitment to international quality standards. This is crucial for our clients exporting to or operating in regulated markets.

Our Expertise and Unwavering Support

With over 16 years of continuous international export experience to 87 countries, we've learned a lot about what our global customers need. More than 50% of our engineers are fluent in English, ensuring clear communication. We were also the first in China in our field to establish a 24/7 after-sales support team. This means we are here to help you with installation, training, troubleshooting, and maintenance, ensuring your equipment runs smoothly and efficiently. We believe in building long-term relationships, and that starts with excellent support. I often tell my team, "Our job isn't done when the machine is shipped; it's done when the customer is succeeding."

Investing in Quality Is Investing in Your Brand

Ultimately, using our advanced molecular distillation systems allows you to produce a superior Omega-3 product. This higher quality translates directly into a stronger brand reputation, increased customer trust, and a better competitive position in the market. It can also open doors to premium pricing and new market segments. We've seen it happen time and again with the tens of thousands of enterprises and individuals we've served globally.

Conclusion

Molecular distillation truly sets the gold standard for Omega-3 purity and concentration. By choosing our advanced systems, you invest in superior product quality, enhanced brand reputation, and lasting market success.