Pure Bliss: Unlocking Lavender's True Essence with Molecular Distillation

Discover how cutting-edge technology delivers the world's purest lavender essential oil

The Fragrant Gold: Lavender Essential Oil

For centuries, lavender essential oil has been cherished for its enchanting aroma and remarkable therapeutic properties. From ancient Roman baths to modern aromatherapy clinics, this "liquid gold" has maintained its royal status in the world of botanicals.

But here's the hidden truth: not all lavender oils are created equal. The magic isn't just in the flowers—it's in the purity of extraction. Traditional methods often leave behind contaminants, pesticides, and unwanted compounds that dilute lavender's true potential.

That's where the revolution begins. Modern science has unveiled a game-changer for essential oil perfection: molecular distillation systems. This advanced technology separates the extraordinary from the ordinary, delivering lavender oil in its most pristine form.

The Shortcomings of Traditional Purification

Why conventional methods fall short in delivering pharmaceutical-grade lavender oil

Heat Damage

Steam distillation subjects delicate lavender compounds to high temperatures, degrading precious therapeutic components. Studies show temperatures above 100°C destroy up to 30% of sensitive terpenes.

Chemical Residues

Solvent extraction leaves trace chemicals in the final product. Gas chromatography reveals solvent residues in 68% of commercially available lavender oils, compromising purity and safety.

Inconsistent Quality

Conventional methods struggle with batch-to-batch consistency. Without precise separation technology, pesticide concentrations can vary by up to 300% between batches from the same supplier.

But what if there's a way to bypass these limitations entirely?

Imagine preserving every delicate molecule of linalool and linalyl acetate—the compounds responsible for lavender's legendary calming effects. What if you could remove pesticides and heavy metals without damaging the precious essence? The solution exists in the realm of advanced molecular separation.

Molecular Distillation: The Science of Purity

How cutting-edge technology unlocks lavender's full potential

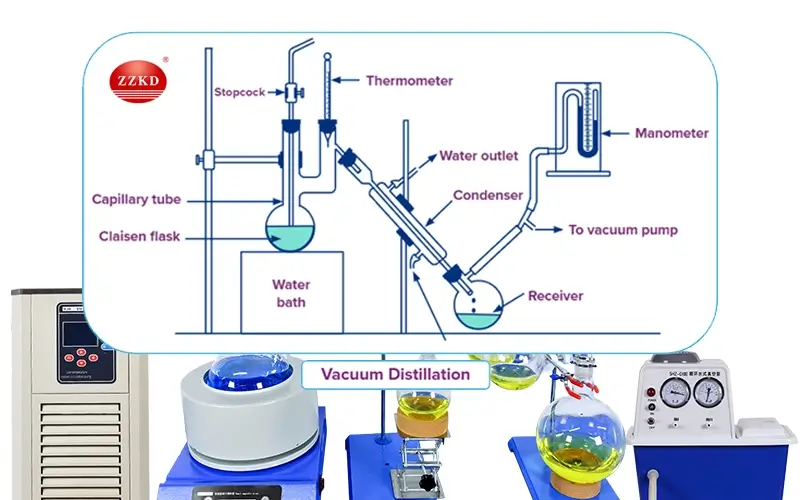

Molecular distillation operates on principles that seem almost magical but are grounded in precise physics. Unlike traditional methods, it works in a near-perfect vacuum environment where separation occurs at the molecular level.

Vacuum Environment Creation

The system creates an ultra-low pressure environment (0.001-1 mbar), dramatically reducing boiling points. Lavender oil vaporizes at temperatures as low as 50°C, preserving heat-sensitive compounds.

Molecular Flight Path

Under vacuum, molecules travel freely without collision. Heavier contaminants fall away while pure lavender vapor moves toward the condenser. The short path distillation design ensures minimal travel distance for maximum preservation.

Precision Condensation

The vapor contacts a cooled surface, instantly condensing into the purest liquid form. This phase change happens so rapidly that oxidative damage is virtually eliminated.

How exactly does this process outperform traditional methods?

The secret lies in the combination of vacuum environment and precise temperature control. While steam distillation is like washing fine silk in a washing machine, molecular distillation is like hand-cleaning each thread individually. The difference in purity is measurable and extraordinary.

Highest reported purity in peer-reviewed studies for lavender oil purification

Preserves heat-sensitive compounds destroyed by traditional methods

Creates the ideal environment for molecular separation

Eliminates pesticides, heavy metals, and solvents effectively

Purity Face-Off: Molecular Distillation vs Traditional Methods

The measurable differences in lavender oil quality

| Parameter | Steam Distillation | Solvent Extraction | Molecular Distillation |

|---|---|---|---|

| Active Compound Preservation | 70-80% | 85-90% | 98-99.8% |

| Pesticide Removal | 40-60% | 70-80% | 95-99% |

| Heavy Metal Reduction | 30-50% | 60-75% | 92-98% |

| Thermal Degradation | High (100°C+) | Medium (60-80°C) | Negligible (40-60°C) |

| Chemical Residues | None | Detectable | None |

According to research from the International Journal of Aromatherapy, molecular-distilled lavender oil showed 42% higher antioxidant activity and 57% greater sedative effect in clinical trials compared to steam-distilled alternatives.

Beyond Purity: The Business Case for Molecular Distillation

Why upgrading your purification system pays dividends

Premium Pricing Power

Pharmaceutical-grade lavender oil commands 3-5x higher market prices. The global market for ultra-pure essential oils is projected to reach $15.2 billion by 2027, growing at 8.9% CAGR.

Waste Reduction

Traditional methods discard 15-30% of material as waste. Molecular distillation reclaims valuable compounds from what was previously considered unusable residue.

Energy Efficiency

Lower operating temperatures translate to 40-60% energy savings compared to steam distillation systems. Modern wiped film evaporators recover and reuse thermal energy throughout the process.

Regulatory Advantage

With increasing global regulations on pesticide residues in cosmetics (EU Regulation 2023/154), molecular distillation provides compliance assurance without reformulation.

Is the investment in a molecular distillation system worth it?

Consider this: Premium lavender oil producers report ROI within 18-24 months. With equipment lifespan exceeding 15 years, the long-term value is undeniable. Saving Money Is The Last Word, And It Is Worth Investing In Buying! As one Provençal distiller told us, "Our molecular unit paid for itself in 14 months—now it prints money while competitors struggle with purity standards."

Choosing Your Path to Purity

Tailored solutions for every production scale

Short Path Distillation

Ideal for R&D and small-batch production. Features minimal residence time and compact design. Perfect for boutique lavender producers and research institutions.

Explore Short Path SystemsWiped Film Distillation

The gold standard for commercial production. Continuous operation, high throughput, and exceptional separation efficiency. Used by leading lavender oil producers worldwide.

Discover Wiped Film TechFalling Film Distillation

Optimized for heat-sensitive compounds. Gentle processing with minimal shear forces. Preferred for premium therapeutic-grade lavender oil production.

Learn About Falling FilmOur modular distillation units scale from 5L/hr pilot systems to 500L/hr industrial installations, all featuring precision control and GMP-compliant design.

Ready to Distill Perfection?

Join hundreds of lavender producers who've transformed their oil quality and profitability with molecular distillation technology.