Molecular Distillation: The Core of Waste Lubricating Oil Regeneration

Discover how cutting-edge technology is turning hazardous waste into valuable resources while protecting our planet

The Dirty Truth About Used Lubricating Oil

Every year, the world generates over 25 million tons of used lubricating oil. That's enough to fill more than 10,000 Olympic-sized swimming pools! Traditionally, this hazardous waste was either burned, dumped, or buried - causing massive environmental damage.

What happens to used engine oil after an oil change?

Most of it ends up as hazardous waste, polluting our soil and water. But with molecular distillation technology, we can transform this environmental liability into valuable base oils. Instead of contaminating our planet, waste oil undergoes a remarkable rebirth, becoming as good as new through advanced purification processes.

This is where molecular distillation systems come into play. These technological marvels are revolutionizing waste oil regeneration, turning what was once pollution into premium reusable lubricants. According to the Environmental Protection Agency, recycling just 2 gallons of waste oil can generate enough electricity to run the average household for almost 24 hours!

Molecular Distillation Demystified

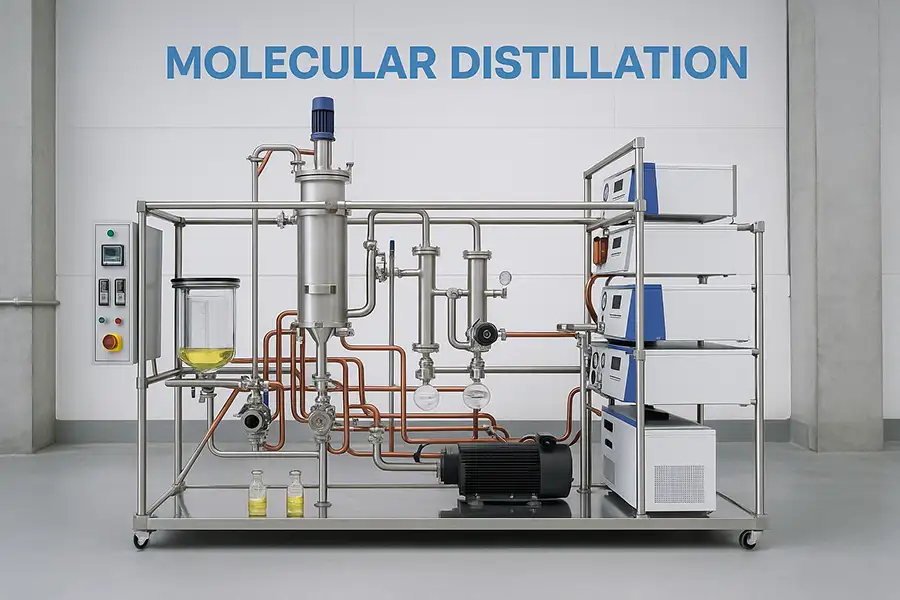

At its core, molecular distillation is a separation process that operates under extremely low pressure (high vacuum), allowing substances to evaporate at much lower temperatures than normal. This gentle treatment preserves the quality of the base oils while removing contaminants.

The Molecular Distillation Process

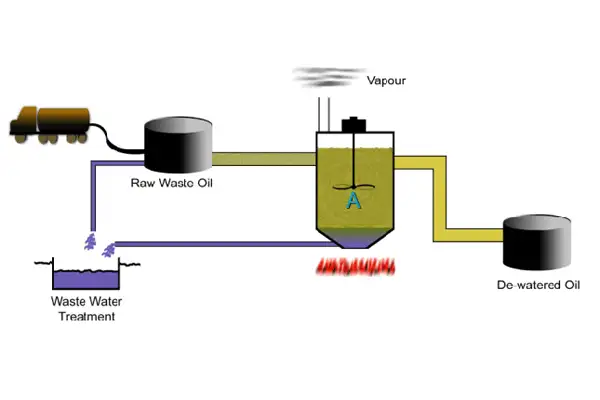

Pre-treatment

Waste oil is dehydrated and filtered to remove water and solid particles

Vacuum Distillation

Oil enters the molecular distillation system where it's exposed to high vacuum and controlled heat

Separation

Different components evaporate at specific temperatures and are collected separately

Purification

Base oils are further refined to meet quality standards

How is molecular distillation different from regular distillation?

Traditional distillation operates at atmospheric pressure, requiring high temperatures that can damage sensitive oils. Molecular distillation uses a high vacuum environment, lowering boiling points dramatically. This gentle approach preserves the molecular structure of the base oils, resulting in higher quality products. Plus, the short path between evaporation and condensation in systems like short path molecular distillation minimizes degradation.

Why Molecular Distillation Rocks for Oil Regeneration

Environmental Superpowers

According to the International Energy Agency, recycling oil through molecular distillation reduces CO2 emissions by up to 80% compared to producing virgin base oils. Every gallon regenerated means one less gallon of hazardous waste contaminating our ecosystems.

Economic Benefits That Make Sense

Saving Money Is The Last Word, And It Is Worth Investing In Buying! A high-quality molecular distillation apparatus pays for itself in 2-3 years through:

Reduced disposal costs (hazardous waste disposal is expensive!)

Revenue from selling regenerated base oils

Lower raw material costs for lubricant manufacturers

Energy savings compared to traditional refining

Is it really cost-effective to regenerate waste oil with molecular distillation?

Absolutely! With recovery rates reaching 95%, the economics are compelling. A study by the American Petroleum Institute found that regenerated base oils cost 40-60% less to produce than virgin equivalents. Plus, with the growing demand for sustainable products, regenerated oils command premium prices in the marketplace. The initial investment in molecular distillation equipment typically pays back within 18-36 months.

Molecular Distillation vs. Traditional Methods

Not all recycling methods are created equal. Here's how molecular distillation stacks up against alternatives:

| Method | Oil Quality | Energy Use | Environmental Impact |

|---|---|---|---|

| Molecular Distillation | Near-virgin quality | Low | Minimal |

| Acid-Clay Treatment | Medium quality | Medium | Hazardous waste generated |

| Re-refining | Variable quality | High | Significant emissions |

| Incineration | No oil recovery | Medium | Air pollution |

Molecular distillation outperforms traditional methods in every category, especially when using advanced systems like wiped film molecular distillation or falling film evaporators.

Key Advantages

Low-Temperature Operation

Prevents thermal degradation of oils

High Recovery Rates

Up to 95% of base oil reclaimed

Exceptional Purity

Removes additives, contaminants, and oxidation products

Energy Efficient

Uses 50% less energy than traditional refining

Ready to Transform Your Waste Oil?

Discover how molecular distillation can turn your environmental liability into a revenue stream

Request a Quote TodayIndustry Impact

The waste oil regeneration market is growing at 5.8% annually as industries embrace circular economy principles.

Saving Money Is The Last Word, And It Is Worth Investing In Molecular Distillation!

With payback periods under 3 years and growing market demand for sustainable products, molecular distillation systems deliver exceptional ROI while protecting our planet.

Learn More About Our Technology