Unlock Nature's True Colors

How Molecular Distillation Revolutionizes Natural Pigment Processing

Discover the cutting-edge technology that's transforming how we extract, concentrate, and purify nature's most vibrant pigments - without compromising their brilliance or nutritional value.

Explore the Science

The Colorful World of Natural Pigments

From the vibrant red of beetroot to the deep green of spinach, natural pigments are nature's artwork. But extracting and preserving these delicate compounds has always been a challenge for scientists and manufacturers.

Traditional methods often involve high temperatures that degrade sensitive compounds, solvents that leave toxic residues, or processes that strip away valuable nutrients along with impurities.

Enter molecular distillation - the game-changing technology that's revolutionizing how we process natural pigments. This advanced separation technique operates at temperatures far below the boiling point of sensitive compounds, preserving their color, potency, and nutritional value.

Why do conventional methods fail with delicate natural pigments?

Most pigments are heat-sensitive and chemically fragile. Traditional distillation or solvent extraction methods expose them to damaging high temperatures or leave behind toxic residues that contaminate the final product and limit its applications.

The Molecular Magic: How It Works

Molecular distillation operates on principles that seem almost magical - but it's pure science!

Desolventization

First, solvents used in initial extraction must be completely removed. Molecular distillation achieves this at low temperatures, preserving pigment integrity while eliminating every trace of solvent.

Concentration

Next, the pigment solution is concentrated by removing excess carrier oils or liquids. Our molecular distillation systems do this gently, preventing thermal degradation.

Purification

Finally, impurities like pesticides, heavy metals, or unwanted compounds are removed. The result? Ultra-pure pigments with unparalleled color intensity and nutritional value.

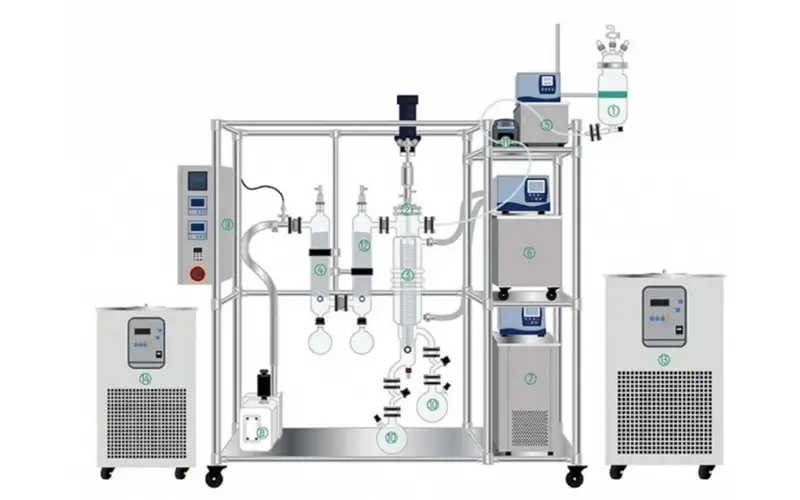

The Heart of the System

At the core of this technology is the evaporation chamber where magic happens under vacuum. The extremely low pressure allows compounds to evaporate at much lower temperatures than normal.

Specialized systems like wiped film molecular distillation use a rotating wiper to create a thin film of material, maximizing surface area for efficient evaporation.

Why Industry Leaders Choose Molecular Distillation

Gentle Processing

Operates at temperatures 50-100°C lower than conventional methods, preserving heat-sensitive compounds.

Unmatched Purity

Removes solvents, pesticides, heavy metals, and other contaminants to undetectable levels.

Superior Yields

Recovers up to 95% of valuable compounds that traditional methods destroy.

Cost Efficiency

Saving Money Is The Last Word, And It Is Worth Investing In Buying! Reduced processing time and higher quality output mean faster ROI.

Higher pigment recovery rates compared to conventional methods

Lower processing temperatures preserving nutrient content

Solvent removal efficiency ensuring product safety

How does molecular distillation compare to other separation technologies?

Unlike simple distillation, molecular distillation operates under high vacuum with very short exposure times. Compared to techniques like chromatography, it offers much higher throughput at lower operational costs. For heat-sensitive compounds like natural pigments, it's simply unbeatable!

Where Molecular Distillation Shines

Transforming industries with pure, vibrant natural pigments

Food & Beverage Coloring

Producing stable, vibrant natural food colorings that replace synthetic dyes. From candy to beverages, molecular-distilled pigments provide intense color without artificial additives.

Cosmetics & Personal Care

Creating pure, skin-friendly color cosmetics. Lipsticks, eyeshadows, and blushes gain their vibrant hues from contamination-free natural pigments processed through short path molecular distillation.

Nutraceuticals & Supplements

Concentrating antioxidant-rich pigments like carotenoids and anthocyanins while preserving their nutritional value. The result? More potent supplements with higher bioavailability.

Natural Textile Dyes

Producing eco-friendly textile dyes with exceptional color fastness. Fashion industry leaders are turning to molecular-distilled natural pigments to meet growing consumer demand for sustainable products.

Molecular Distillation vs. Conventional Methods

Why advanced separation technology makes all the difference

| Factor | Molecular Distillation | Conventional Methods |

|---|---|---|

| Processing Temperature | Low (50-200°C) | High (200-300°C) |

| Solvent Residue | None Detected | Often Present |

| Pigment Degradation | Minimal (0-5%) | Significant (20-50%) |

| Heavy Metal Removal | >99.5% Efficiency | Limited Removal |

| Operational Costs | Lower Long-term | Variable |

| Final Product Value | Premium Quality | Standard Grade |

Is molecular distillation worth the investment for small producers?

Absolutely! While the initial investment might be higher, the superior quality and yield mean you'll command premium prices in the market. Modular systems like our compact molecular distillation units make this technology accessible to producers of all sizes. The efficiency gains typically pay back the investment within 18-24 months.

Ready to Transform Your Pigment Processing?

Join hundreds of forward-thinking companies who've already upgraded to molecular distillation technology. Our experts will help you select the perfect system for your specific needs.

Request Custom ConsultationOr explore our range of molecular distillation equipment