Are you finding it hard to understand THC extraction? Getting pure, strong distillates can seem complicated. We make it clear how top-quality THC distillate is produced.

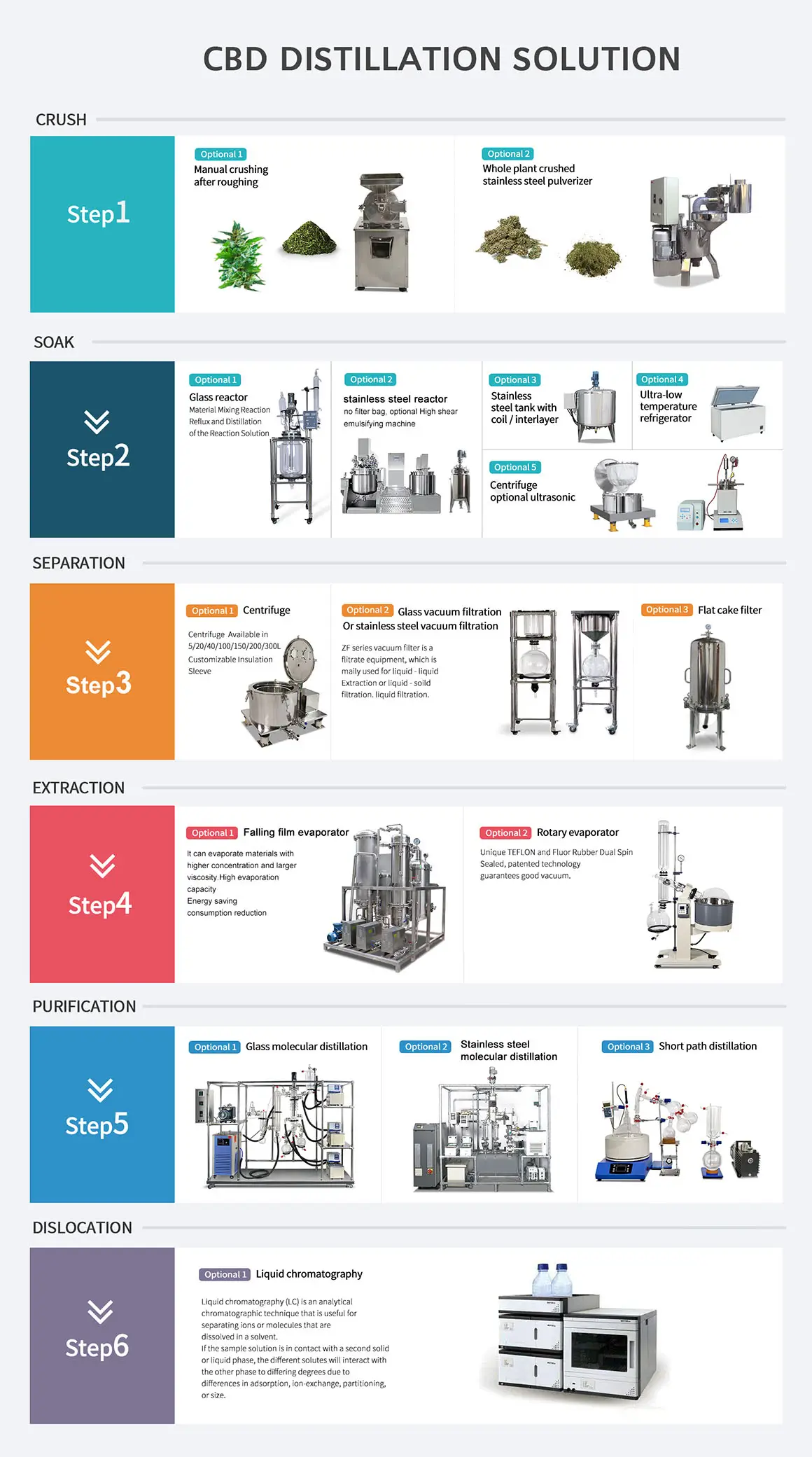

THC distillate is extracted through several careful steps. This usually starts with pulling out cannabinoids using solvents like ethanol or CO2. Then, it involves winterization, decarboxylation, and finally, purification with distillation, often short-path molecular distillation, to get very high THC levels.

THC distillate is becoming very popular, and for good reason. It's a highly refined cannabis product. Many people like it because it's strong and versatile. As a company that makes and exports the equipment for this, we see its demand growing worldwide. I've been in this business for over 16 years, and the technology to make pure distillates has come a long way. It's fascinating to see how raw plant material transforms into such a clean product.

What is THC Distillate?

Is the world of cannabis concentrates confusing? THC distillate is special because of its pureness. Let's look at what makes it different.

THC distillate is a very pure cannabis concentrate. It has extremely high THC levels because most other plant stuff and cannabinoids are taken out. It looks like a thick, golden, clear oil.

Understanding THC distillate is key to appreciating its value. From my experience in providing equipment for its production, here’s a deeper look:

Appearance and Consistency

THC distillate is usually a thick liquid, almost like honey. Its color can range from perfectly clear to a light golden amber. This clean look is a sign of its purity. When we were first developing our distillation equipment, achieving that beautiful golden clarity consistently was a major goal. It showed our machines were doing their job right by removing unwanted parts like chlorophyll and waxes.

Purity and Potency

This is where distillate truly shines. It can often contain over 90% THC, sometimes even reaching 99%. This means it’s one of the strongest cannabis products available. Such high potency is achieved because the distillation process is very good at separating THC from almost everything else. We've seen customers achieve remarkable purity levels using our molecular distillation units, which makes us proud.

Lack of Flavor and Aroma

During the distillation process, terpenes, which give cannabis its smell and taste, are usually removed along with other compounds. This means pure distillate often has very little to no flavor or aroma of its own. Some producers add terpenes back into the distillate later to create specific flavor profiles. This is a common practice I’ve observed with many of our clients who cater to diverse consumer preferences.

Versatility in Use

Because it's so pure and often tasteless, THC distillate is very versatile. It can be used in vape pens, added to edibles, used for dabbing, or as a base for other cannabis products. This flexibility is a big reason for its popularity. Our clients use our equipment to produce distillate for all these applications, showcasing its adaptability.

Why is Extraction Necessary for THC Distillate?

Do you wonder why we can't just use raw cannabis? To get pure THC for distillate, extraction is absolutely needed. We explain why this step is so important.

Extraction is needed to separate and concentrate THC from the cannabis plant. Raw cannabis has many compounds; extraction isolates THC, boosts its strength, and makes it ready for different products.

The journey from plant to pure distillate involves several critical transformations. Here's why each part of the extraction process is so vital. I've seen first-hand how skipping or poorly performing these steps impacts the final product quality.

Concentrating THC

Raw cannabis flowers typically contain THC levels ranging from 10% to 30%, or even a bit higher for some potent strains. However, the rest is plant matter, moisture, and other compounds. Extraction processes are designed to strip away this bulk material and significantly increase the concentration of THC and other cannabinoids. This concentration is the first step towards the high potency found in distillates. Our clients aim for maximum yield from their plant material, and efficient initial extraction is key.

Removing Undesirable Impurities

The cannabis plant contains more than just cannabinoids and terpenes. There are chlorophyll (which gives plants their green color), waxes, fats, lipids, and sometimes contaminants like pesticides or heavy metals if the plant was exposed to them. These impurities can affect the taste, smoothness, appearance, and safety of the final product. Extraction and subsequent refinement steps like winterization and distillation are crucial for removing these unwanted components. We always advise our customers that a cleaner crude oil makes the final distillation easier and results in a better product.

Activating THC (Decarboxylation)

In raw cannabis, THC is mostly present in its acidic form, THCA (tetrahydrocannabinolic acid). THCA isn't psychoactive until it's heated. The process of converting THCA to active THC is called decarboxylation. This usually involves carefully heating the extracted oil. While some decarboxylation might occur during initial extraction or distillation if temperatures are high enough, it's often a specific, controlled step to ensure full activation. Many processors using our equipment perform decarboxylation before the final distillation stage.

Creating Versatile and Stable Products

Extracting THC into an oil form makes it much more versatile than raw plant material. This oil can be precisely dosed, has a longer shelf life if stored properly, and can be easily incorporated into a wide variety of products, from vape cartridges to edibles and topicals. The purity of distillate further enhances this versatility. I remember a client who switched to producing distillate and was amazed at how it opened up new product lines for their business.

What are the Main Steps in THC Distillate Extraction?

Feeling lost in the many steps of extraction? It's a careful and exact process. Let's simplify the main stages needed to create pure THC distillate.

The main steps are: 1. Crude Extraction (using solvents like ethanol or CO2). 2. Winterization (to remove fats and waxes). 3. Decarboxylation (to activate THC). 4. Distillation (to purify THC, often using short-path molecular distillation).

Creating high-quality THC distillate is a journey with several important stops. As an equipment manufacturer, we provide tools for some of the most critical later stages, but we understand the whole process. Here’s how it generally flows:

Step 1: Crude Oil Extraction

This is the starting point. The goal is to get the cannabinoids and terpenes out of the plant material. Common methods include using solvents like ethanol (popular for its efficiency and ability to extract a broad spectrum of compounds), CO2 (known for its clean, tunable extractions), or hydrocarbons like butane and propane (which can result in flavorful extracts but require careful handling). Each method has pros and cons regarding safety, cost, and the type of extract produced. The result of this step is a "crude" oil, which still contains many impurities.

Step 2: Winterization (or Dewaxing)

Crude oil, especially from ethanol extraction, often contains fats, waxes, and lipids from the plant. These can make the final product cloudy or harsh. Winterization removes them. The oil is mixed with ethanol and then frozen for an extended period (e.g., 24-48 hours). The low temperature causes the waxes and fats to solidify. Then, this mixture is filtered while cold, leaving the undesirable compounds behind and resulting in a cleaner oil. I've seen many clients improve their product's clarity significantly with a good winterization setup.

Step 3: Decarboxylation

As mentioned earlier, this step converts the non-psychoactive THCA into the psychoactive THC. This is typically done by heating the winterized oil to a specific temperature for a certain amount of time. Precise control is important here to avoid degrading the THC. Many of our reactor vessels are used for this stage, allowing for controlled heating and mixing.

Step 4: Distillation (The Final Polish)

This is where the magic of purification happens, and it's our specialty. The decarboxylated oil is fed into a distillation system. Short-path molecular distillation is the most common and effective method for THC. Under a deep vacuum and with precise temperature control, THC and other cannabinoids are separated based on their different boiling points and molecular weights. This step removes remaining impurities like chlorophyll, pigments, and any residual solvents or pesticides, resulting in a highly potent, clear THC distillate. Our molecular distillation equipment is designed to perform this separation with high efficiency and precision.

How Does Molecular Distillation Work for THC?

Want to know the "secret" behind molecular distillation? It's all about careful science. We explain in simple terms how it purifies THC to such high levels.

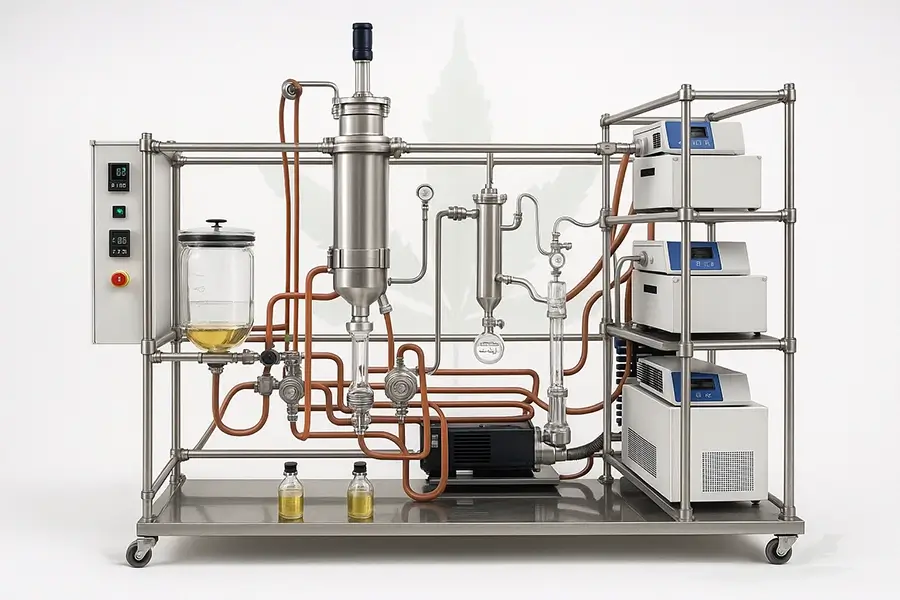

Molecular distillation (often short-path) refines THC by heating crude cannabis oil under a strong vacuum. This lets different cannabinoids and terpenes separate based on their molecular weights and boiling points over very short distances, which reduces heat damage.

Molecular distillation is a cornerstone technology for producing high-purity THC distillate. As a manufacturer with over 16 years of experience in this area, we've seen its impact. Here’s how our equipment helps achieve this:

Key Principles: High Vacuum and Short Path

Molecular distillation works under a very high vacuum. This is super important because it lowers the boiling points of compounds like THC. It’s like how water boils at a lower temperature on a high mountain. With a lower boiling point, THC can turn into vapor at much cooler temperatures, which stops it from breaking down from too much heat. The "short path" part means the THC vapor only travels a tiny distance – usually a few centimeters – before it hits a cool surface (the condenser) and becomes liquid again. This short journey further reduces the chance of the THC degrading. We design our systems to create and keep these deep vacuums and exact short paths for the best results.

The Process: Evaporation and Condensation on a Wiped Film

In our molecular distillation units, the crude cannabis oil is spread onto a heated, rotating surface inside the vacuum chamber. A system of wipers, like rollers or blades, creates a very thin film of this oil. This thin film helps the oil heat evenly and makes the THC evaporate quickly. As the film moves across the hot surface, different parts of the oil vaporize. The THC vapor then travels that short distance to an internal condenser, which is kept cool. Here, the THC vapor turns back into a very pure liquid and is collected. Other heavier stuff or impurities are left behind and collected separately. We've spent years perfecting our wiper and heating designs to make sure the separation is as good as it can be.

Separation by Molecular Weight and Volatility

The real strength of molecular distillation is its power to separate compounds that have similar boiling points but different molecular weights or how easily they vaporize. Under high vacuum, molecules leave the hot surface based on these traits. Lighter molecules, or those that vaporize at lower temperatures in a vacuum, will evaporate first. This allows for very precise separation. For example, terpenes can be separated out first. Then, THC can be separated from other cannabinoids or heavier impurities. Our systems give operators fine control over temperature and vacuum, so they can target specific compounds and get the pure distillate they want.

Continuous Refinement for Top Quality

We’ve been making and sending this equipment overseas for many years. This experience has taught us that reliable performance is vital. Things like an even thin film, a stable vacuum, and exact temperature control all greatly affect the final THC distillate quality. We are always improving our designs based on what our customers tell us and our own research. This focus on quality and new ideas is why people all over the world trust our equipment for their extraction needs. It’s about making "Made in China" synonymous with "International Quality" in this field.

What are the Advantages of Using Molecular Distillation for THC?

Are you looking for the best way to purify THC? Molecular distillation has some big benefits. Find out why it's a leading choice for quality distillate.

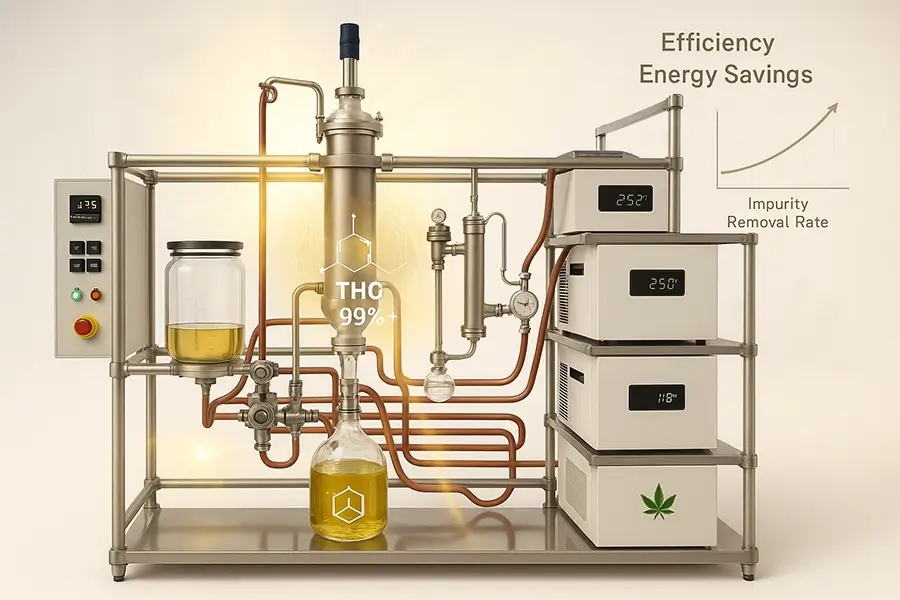

Molecular distillation provides very high purity and strength, excellent separation of cannabinoids, removal of impurities like pesticides, and less heat damage to THC because of low temperatures and short processing times. This creates a top-quality distillate.

Choosing the right purification method is crucial for producing premium THC distillate. From my experience working with producers globally, molecular distillation consistently stands out for several key reasons. It’s not just about getting THC; it’s about getting high-quality, safe THC.

Achieving Unmatched Purity & Potency

This is the primary advantage. Molecular distillation can separate THC from nearly all other compounds, leading to potencies often exceeding 90% and sometimes even up to 99%. This level of purity is difficult to achieve with other methods. The process is highly selective. For example:

| Compound/Material | Effectiveness of Molecular Distillation |

|---|---|

| THC | Highly concentrated (often >90-99%) |

| Other Cannabinoids (CBD, CBG, etc.) | Can be separated into different fractions if desired |

| Terpenes | Typically removed (can be collected separately) |

| Waxes and Lipids | Effectively removed (especially if pre-treated) |

| Pigments (e.g., Chlorophyll) | Effectively removed, leading to clear/amber color |

| Pesticides & Residual Solvents | Significantly reduced or eliminated due to differences in volatility |

We design our equipment with precision in mind to help our clients hit these high purity targets consistently.

Minimizing Thermal Degradation

THC is sensitive to heat. Prolonged exposure to high temperatures can degrade it into other compounds like CBN, reducing its potency and altering its effects. Molecular distillation operates under a high vacuum, which lowers the boiling point of THC. This, combined with the short residence time (the oil is heated for only a very brief period as it passes through the system), significantly minimizes heat-related damage. This is a huge benefit I always emphasize to clients concerned about product integrity.

Efficient Removal of Impurities

Beyond just concentrating THC, molecular distillation is excellent at removing a wide range of unwanted substances. This includes residual solvents from the initial extraction, pesticides that might have been on the plant, and various pigments or other plant byproducts. The result is a cleaner, safer, and more appealing final product. This is critical for meeting regulatory standards and consumer expectations in many markets.

Scalability for Production Needs

Molecular distillation technology can be scaled from small laboratory setups for research and development to large industrial systems for commercial production. As a manufacturer, we offer a range of equipment sizes to cater to different operational scales. I’ve seen businesses start with our smaller units and then upgrade as their demand grows. This scalability ensures that as a producer's business expands, their purification capabilities can grow with them, maintaining consistent quality.

Conclusion

Extracting THC distillate involves careful steps, with molecular distillation being key for top purity and potency. This advanced process ensures a high-quality final product.