Struggling to achieve the purest cannabis concentrates? Impurities and unwanted compounds can ruin your final product. You need a reliable method for high-grade refinement.

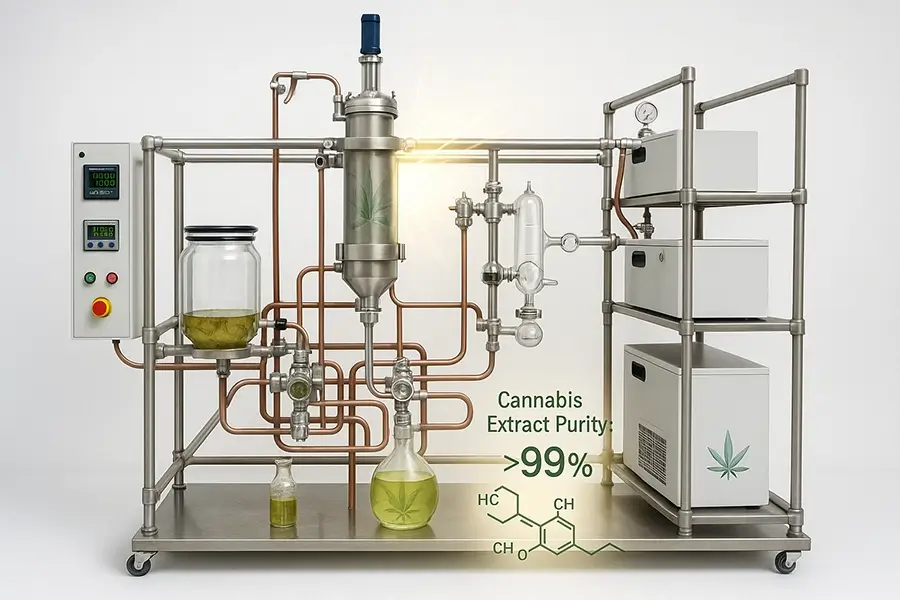

Cannabis molecular distillation is a powerful purification technique. It separates cannabinoids from impurities at a molecular level. This process yields exceptionally pure and potent cannabis extracts, meeting the highest market standards. We have seen it transform product lines in our 16 years of exporting equipment.

This advanced separation process is becoming essential for producers who want to offer premium products. As a company specializing in laboratory and production equipment for over 16 years, we have witnessed its impact firsthand. Let's explore this technology more.

What Exactly is Cannabis Molecular Distillation and How Does It Work?

Confused by the science behind super-pure cannabis oils? Traditional methods often leave behind undesirable elements. Understanding the core process is key to better products.

Molecular distillation, often called short-path distillation, refines pre-extracted cannabis oil under deep vacuum. This allows separation based on molecular weight at lower temperatures, preserving delicate cannabinoids and terpenes effectively. It is a precise separation technique we specialize in.

Let me break this down. The "short path" in short-path distillation is very important. It means the distance that the vaporized cannabis compounds travel before they are condensed is very short. This happens inside the equipment. Why is this good? It reduces the chance of these valuable compounds being lost or degrading. This is especially true for sensitive molecules like cannabinoids and terpenes.

Then there is "deep vacuum." We create a very low-pressure environment inside the distillation apparatus. This significantly lowers the boiling points of the different compounds in the cannabis extract. So, we do not need to use very high heat, which can damage the cannabinoids or terpenes. Our equipment, which includes ISO9001 and CE certified components, is designed to achieve and maintain these deep vacuum levels reliably.

How Separation Occurs:

The crude cannabis extract is fed into the heated evaporator. Under vacuum, different compounds vaporize at different temperatures based on their molecular weights and volatility. Lighter molecules, like some terpenes, vaporize first. Then, cannabinoids like THC and CBD vaporize. Heavier materials, like waxes, chlorophyll, and degraded pigments, are left behind as residue. The vapors then travel the short distance to a condenser, where they cool and turn back into liquid fractions. We collect these fractions separately – typically a terpene fraction, the main cannabinoid fraction, and the residue. This careful separation is what gives us such pure end products.

Why is Molecular Distillation a Game-Changer for Cannabis Product Purity?

Are your cannabis extracts falling short of customer expectations for purity and potency? In a competitive market, quality is everything. You need an edge, and this is where we can help.

Molecular distillation excels at removing contaminants like pesticides, chlorophyll, waxes, and unwanted plant matter. This results in a clearer, cleaner, and more potent final product, enhancing its value and appeal. We have seen customers achieve over 99% cannabinoid purity with our systems.

The impact on product quality is significant. Think about what consumers want: clean, safe, and potent products. Molecular distillation helps you deliver exactly that. For example, chlorophyll can give extracts a dark color and a harsh, plant-like taste. Waxes can make vape cartridges clog or give a poor dabbing experience. Pesticides, of course, are a major safety concern. Our molecular distillation equipment efficiently removes these.

The result is an extract that is not only more potent because the cannabinoids are concentrated, but also much more visually appealing – often a beautiful golden or light amber color. This clarity is a hallmark of high-quality distillate. Furthermore, by removing unwanted compounds, the flavor and aroma of the final product can be much cleaner, allowing the natural terpene profile (if preserved or reintroduced) to shine. This is critical for products like vape pens and edibles where consumer experience is paramount. For over 16 years, we've focused on providing equipment that meets these exacting international standards for purity and safety, and we see molecular distillation as key to that.

Key Benefits We've Observed:

Greatly Increased Potency: Concentrating cannabinoids by removing non-active components.

Improved Clarity and Color: Creating a visually appealing, often golden, oil.

Removal of Impurities: Eliminating pesticides, waxes, chlorophyll, and other undesirable materials.

Enhanced Flavor Profile: Producing a cleaner taste, and allowing for terpene reintroduction for desired effects.

Product Versatility: Ideal for creating distillates used in vape cartridges, edibles, tinctures, and topicals.

What Key Factors Should You Consider When Choosing Molecular Distillation Equipment for Cannabis?

Investing in new equipment is a big decision, right? Choosing the wrong molecular distillation setup can lead to inefficiencies and lower quality. You need reliable gear that fits your needs.

Look for equipment with precise temperature and vacuum control, durable materials like borosilicate glass or stainless steel, and a design that minimizes residence time. Consider throughput capacity and ease of cleaning. Our 16 years of production and export experience have taught us these are critical.

Let me expand on these points based on what we've learned as a specialized manufacturer. Precise temperature control is not just about heating the evaporator; it is also about accurately cooling the condenser to ensure efficient vapor capture. The vacuum system must be robust enough to reach and hold the deep vacuum needed, often below 0.001 mbar. We use high-quality vacuum pumps and measurement tools for this.

Materials are so important. For parts that touch your cannabis oil, you want inert materials. Borosilicate glass 3.3 is excellent because it is resistant to chemicals, handles temperature changes well, and you can see the process. For larger systems or certain components, food-grade stainless steel (like 316L) is also a great choice. All our equipment meets stringent ISO9001 and CE certification standards, reflecting this material quality.

The "residence time" – how long the oil is exposed to heat – should be as short as possible. This minimizes thermal stress on the cannabinoids. Throughput is another big one: will you be processing a few liters a day for R&D, or hundreds for large-scale production? We offer systems of various sizes. Finally, think about cleaning. Easy disassembly and smooth surfaces save time and prevent cross-contamination. We design our units with the operator in mind.

| Feature | Importance for Cannabis Distillation | What We Focus On (ZZKD) |

|---|---|---|

| Precise Temperature Control | Prevents degradation, ensures proper separation of fractions. | Advanced, stable heating and cooling systems. |

| Deep Vacuum Capability | Lowers boiling points, protects cannabinoids from heat. | High-performance vacuum pumps and tight-seal designs. |

| Quality Materials (e.g., Borosilicate Glass 3.3, SS316L) | Ensures inertness, durability, product purity, and safety. | Use of certified, high-grade materials. |

| Short Residence Time Design | Minimizes heat exposure to sensitive compounds. | Efficient evaporator and condenser designs. |

| Scalability Options | Meets needs from research labs to full production. | A range of unit sizes from lab to industrial scale. |

| Ease of Cleaning & Maintenance | Reduces downtime, prevents contamination, ensures longevity. | User-friendly designs for easy disassembly and cleaning. |

| Reliable After-Sales Support | Ensures continued operation and assistance when needed. | Our 24/7 global support and technical expertise. |

How Can Our Molecular Distillation Systems Help You Achieve Top-Quality Cannabis Extracts?

Want to consistently produce premium cannabis distillates that stand out? The right equipment partner makes all the difference. You need a solution you can trust from an experienced manufacturer.

Our molecular distillation units are engineered for efficiency, precision, and reliability in cannabis processing. With features born from 16 years of continuous international export experience, we help you maximize yield and purity. We are an integrated factory and exporter, focused only on international markets.

As a company, Zhengzhou Keda Machinery and Instrument Equipment Co.,Ltd. (we often go by ZZKD) has been dedicated to this field for a long time. We were China's first laboratory instrument equipment manufacturer to independently export overseas. This means we understand international quality expectations. Our "Made in China + International Quality" approach means you get high value-for-money products that meet standards like ISO9001 and CE.

Our short-path distillation systems, a core product for cannabis applications, benefit from our continuous R&D. We aim for high-cost-performance and can even discuss customized solutions. For cannabis processors, this means equipment that is tailored to handle the specific challenges of cannabinoid purification. For instance, our systems provide very fine control over feed rate, evaporator temperature, condenser temperature, and vacuum levels. This allows you to precisely separate different cannabinoid fractions and terpenes if desired. I remember a client in North America who was struggling with consistency; after switching to our unit and with some process optimization support from our English-speaking engineers, their product quality became much more stable and praised by their customers.

Furthermore, we stand by our "Worry-Free Global After-Sales." We were the first in China to set up a 24/7 after-sales support team. We know downtime is costly, so we offer prompt responses, free maintenance during the one-year warranty, and lifetime cost-price service. This dedication to support and our market-proven equipment, used by tens of thousands globally, should give you confidence. We welcome technical exchanges and factory visits to show you our commitment directly.

Conclusion

In summary, molecular distillation is vital for high-purity cannabis extracts. Our reliable equipment and deep expertise can help you achieve exceptional results and grow your business in this demanding market.