Struggling with high solvent costs and waste disposal fees? You want to improve your lab's sustainability and bottom line, but traditional methods are slow, inefficient, and require constant supervision.

A modern molecular distillation system is the key. It recycles solvents at over 95% efficiency, drastically cutting new solvent purchases and waste. This technology purifies materials under high vacuum at low temperatures, making it safe for sensitive compounds and boosting overall lab productivity.

For over 16 years, I've seen labs transform their operations with the right equipment. We started our company to solve these exact problems. Many of our clients, from pharmaceutical startups to university research centers, were stuck in a cycle of high operational costs. They needed a reliable way to purify materials without losing valuable solvents or degrading their products. It's not just about saving money; it's about making your entire workflow smarter and more sustainable. We believe that by integrating an efficient recovery system, you don't just upgrade a piece of equipment; you upgrade your entire scientific process.

What Is the Basic Idea Behind Solvent Recovery?

Are you spending too much on fresh solvents and disposal? The constant cycle of buying, using, and discarding chemicals adds up, impacting both your budget and the environment.

Solvent recovery is a process that separates and purifies used solvents from waste mixtures, allowing them to be reused. By using distillation, we can heat a mixture to vaporize the solvent, then cool the vapor back into a pure, clean liquid, ready for another use.

Let's dive deeper into how this works. Think of it like making distilled water, but instead of water, we're purifying valuable industrial solvents like ethanol or hexane. The whole process relies on a simple scientific principle: different substances boil at different temperatures. When you have a mixture of your valuable solvent and some non-volatile waste (contaminants, dissolved products), you can heat it precisely to the boiling point of the solvent.

The Separation Process Step-by-Step

First, the solvent turns into a vapor, leaving the heavier contaminants behind. Next, this pure solvent vapor travels into a separate chamber called a condenser. Here, we cool it down, causing the vapor to turn back into a high-purity liquid. This recovered solvent is then collected and is often just as good as new. It’s a beautifully simple and effective cycle that not only saves a huge amount of money but also makes your lab much more environmentally friendly. The right molecular distillation apparatus automates this for maximum efficiency.

How Does a Wiped Film Evaporator Improve the Process?

Are your heat-sensitive materials getting damaged during distillation? Standard boiling can be too harsh, leading to product degradation and lower yields, which is a frustrating waste of time and resources.

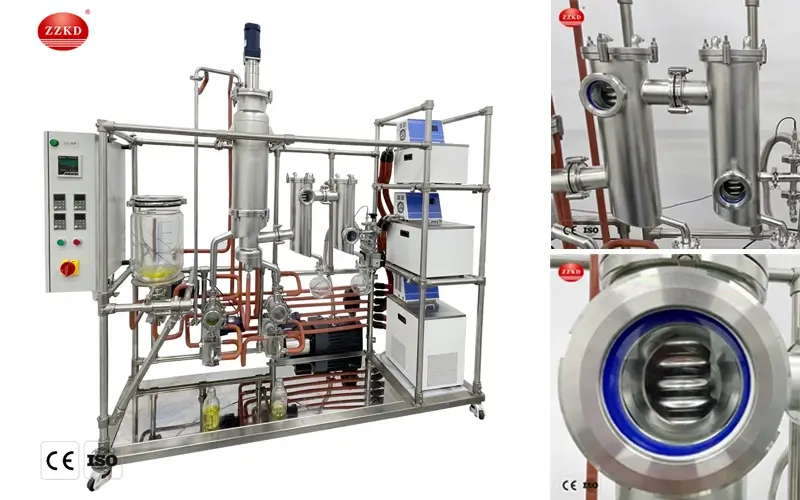

A wiped film evaporator, also known as a wiped film molecular distillation system, uses rotating wipers to spread a very thin layer of the mixture onto a heated surface. This allows for extremely fast and gentle evaporation at lower temperatures, protecting sensitive compounds.

The magic of a wiped film evaporator is all in the "thin film." Traditional distillation heats a whole pot of liquid, which can take a long time and create hot spots that destroy your product. Our system is much smarter. As soon as the feed liquid enters the evaporator, a set of rotating blades spreads it into a microfilm, just fractions of a millimeter thick, across the inner wall of the vessel. This thin layer has a huge surface area, so it heats up and evaporates almost instantly and very evenly. Because the evaporation is so quick, the "residence time"—the amount of time your product is exposed to heat—is reduced to just a few seconds. This is a game-changer for anyone working with delicate materials like vitamins, omega-3s, or pharmaceutical compounds.

Key Advantages of This Technology

This method prevents thermal decomposition, which means your final product is purer and your yield is higher. It also allows us to work with very viscous, thick liquids that would be impossible to process in a standard distillation setup. This is a core part of what we've perfected over the years, ensuring our clients can handle even the most challenging separation tasks.

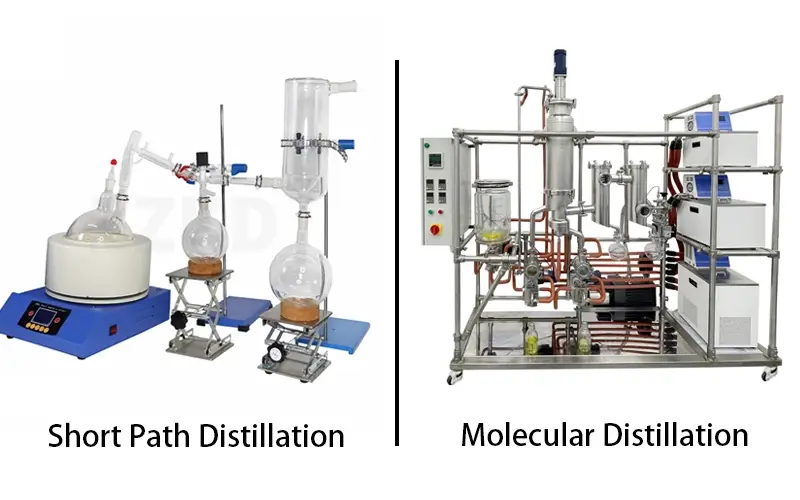

Why Is Short Path Molecular Distillation the Ultimate Solution?

Need the absolute highest purity for your final product? Even with advanced evaporators, some impurities can be hard to separate, especially when dealing with high-value, complex molecules.

Short path molecular distillation is the most advanced form of distillation. It works under a deep vacuum and minimizes the travel distance for vapor molecules from the evaporator to the condenser, preventing any loss and ensuring maximum purity for thermally sensitive, high-boiling-point compounds.

So, what makes the "short path" so special? In this technique, the condenser is placed directly inside the evaporator body. This means the vapor molecules only have to travel a few centimeters before they are cooled and collected. This is crucial because when you're operating under a high vacuum, molecules can easily get lost or react with each other if they have a long way to travel. By making the path incredibly short, we ensure that almost every molecule of your desired product makes it to the condenser. This technique allows for separation at the lowest possible temperatures, providing unparalleled protection for the most fragile compounds.

Comparing Distillation Techniques

| Feature | Standard Distillation | Wiped Film Evaporation | Short Path Distillation |

|---|---|---|---|

| Operating Pressure | Atmospheric | Low Vacuum | High Vacuum (<0.001 mbar) |

| Operating Temperature | High (Boiling Point) | Moderate | Very Low |

| Heat Exposure Time | Hours | Minutes | Seconds |

| Best For | Simple Solvents | Heat-Sensitive Liquids | Highly Sensitive, High MW Compounds |

This table really shows the evolution of distillation technology. For anyone in the pharmaceutical, cannabis, or specialty chemical industries, achieving that final level of purity is everything. It's the difference between a standard product and a premium one. We designed our molecular distiller units to provide this ultimate level of control and precision.

Conclusion

Upgrading to a modern distillation system saves costs, protects products, and boosts lab efficiency. It's a smart investment in quality, sustainability, and your future success. Ready to learn more? Contact us today!