Capturing the True Essence

Have you ever wondered what makes a $300 bottle of perfume fundamentally different from a $30 one? Why some fragrances linger for hours while others vanish within minutes? The secret lies not in mystical ingredients but in a remarkable technology called molecular distillation.

In the fragrance and flavor industry, the battle is all about capturing that fleeting, ethereal essence—the delicate volatile compounds that evaporate at body temperature to create the sensory experience we love. Traditional steam distillation methods can be too brutal for these fragile molecules, often scorching them beyond recognition.

How does molecular distillation differ from boiling a liquid?

Molecular distillation works in a high vacuum environment, reducing the boiling point of materials drastically. This means precious essential oils can vaporize at temperatures below the point where they might degrade, while traditional methods require temperatures that destroy delicate aromatic compounds.

The magic happens at temperatures far lower than you'd imagine—sometimes below 100°F (38°C). By creating intense vacuum environments and using specialized equipment like short path molecular distillation systems, we can preserve the entire molecular profile of the most volatile compounds.

The Numbers Tell the Story

98%

Purity Achieved

with molecular distillation

50-60%

Less Energy

compared to traditional methods

3-5×

Increase in Product Value

using this technology

But it's not just perfumes—molecular distillation is revolutionizing how we extract:

Food essences: True-to-nature vanilla, citrus and coffee flavors

CBD isolates: Pharmaceutical-grade purity

Pharmaceuticals: Purifying sensitive compounds

Essential oils: Unadulterated plant extracts

Can I distill heat-sensitive vitamins in the same system?

Absolutely! The same gentle processing that preserves rose absolue can extract vitamin E from vegetable oils without destruction. Multi-functional molecular distillation systems typically handle botanicals one day and nutritional extracts the next.

Inside the Magic: How Fragrance Perfection Happens

At its core, molecular distillation is all about molecule-by-molecule separation rather than bulk boiling. Here's how the magic unfolds:

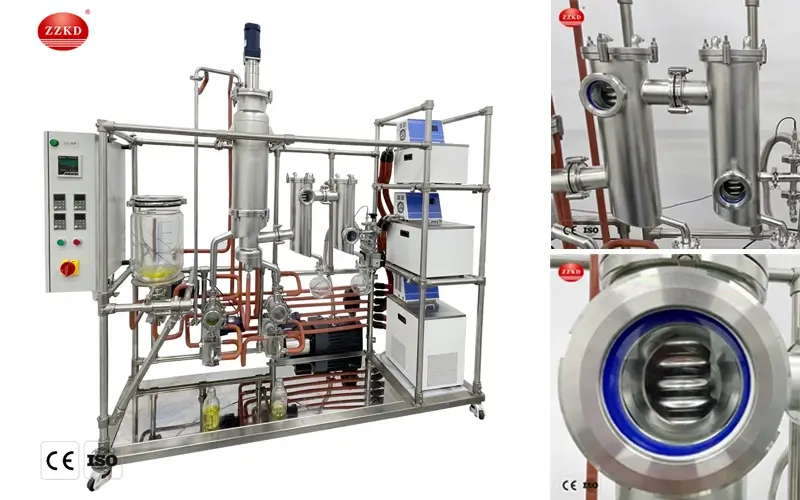

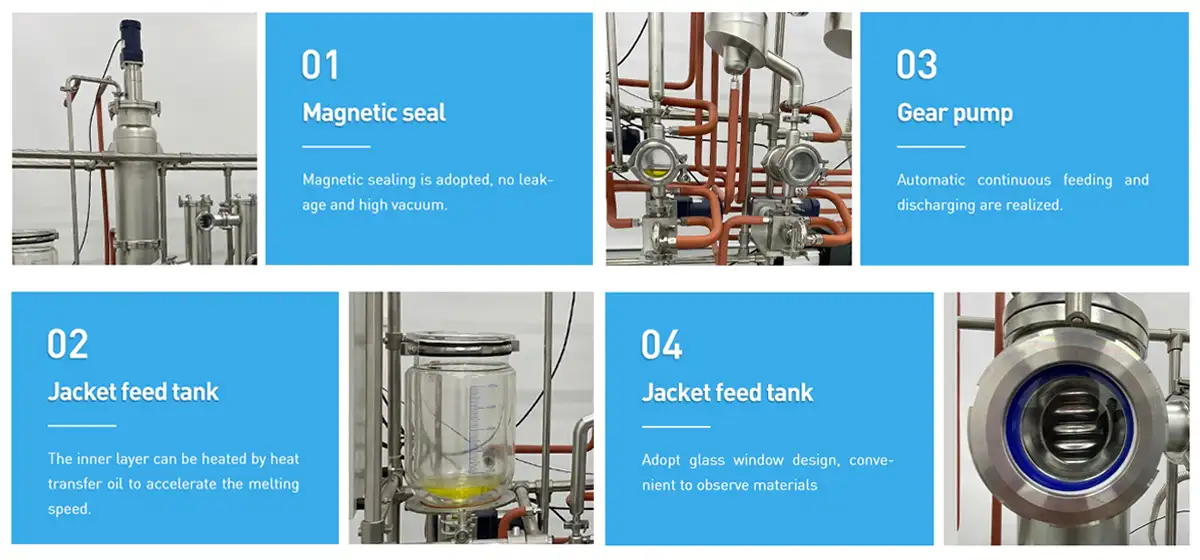

The raw material is introduced into an evaporator under extreme vacuum—sometimes just 0.001 millibars of pressure

A thin film of the material is created via spinning wipers or gravity flow

Molecules vaporize instantly as they reach their evaporation point at the reduced pressure

These vapors travel a very short path to a chilled condenser

Different compounds condense at different surfaces based on molecular weight

"Molecular distillation is the equivalent of examining precious gems under magnification rather than smashing them with a hammer. It lets you work with compounds that simply couldn't survive traditional methods."

Whether you're using wiped film distillation equipment for viscous materials or short path units for high-value isolates, the principles remain the same: gentle separation at the molecular level.

How can I know if my products need molecular distillation?

If you've ever detected an unwanted 'cooked' note in your essential oil or found your fruit flavorings lacking vibrancy, that's nature telling you the heat was excessive. For heat-sensitive compounds that degrade at temperatures above 150°F (65°C), molecular methods become essential rather than optional.

Making the Equation Work: Cost vs Value

Yes, molecular distillation equipment requires higher initial investment. But premium perfume houses understand this fundamental calculus:

Traditional Process

$50/lb

Lower quality product

40% yield of compromised material

Requires expensive additives to mask imperfections

Transitional Solution

$80/lb

Better but inconsistent

70% yield with variable results

Limited market positioning

Molecular Distillation

$150/lb

Premium, authentic product

95% yield of pristine material

Command premium pricing in luxury markets

For mid-sized fragrance houses processing 1,000 liters of material monthly, this value difference translates to over $500,000 in annual revenue uplift—easily justifying the equipment investment within 18 months.

Wondering about the practical numbers? Our detailed molecular distillation price guide breaks down the options for every budget.